BEN-THOMAS Large-Span Corrugated Arch Plate Manufacturing Machine: High-Efficiency Production for Modern Bridge and Culvert Projects

News 2025-12-20

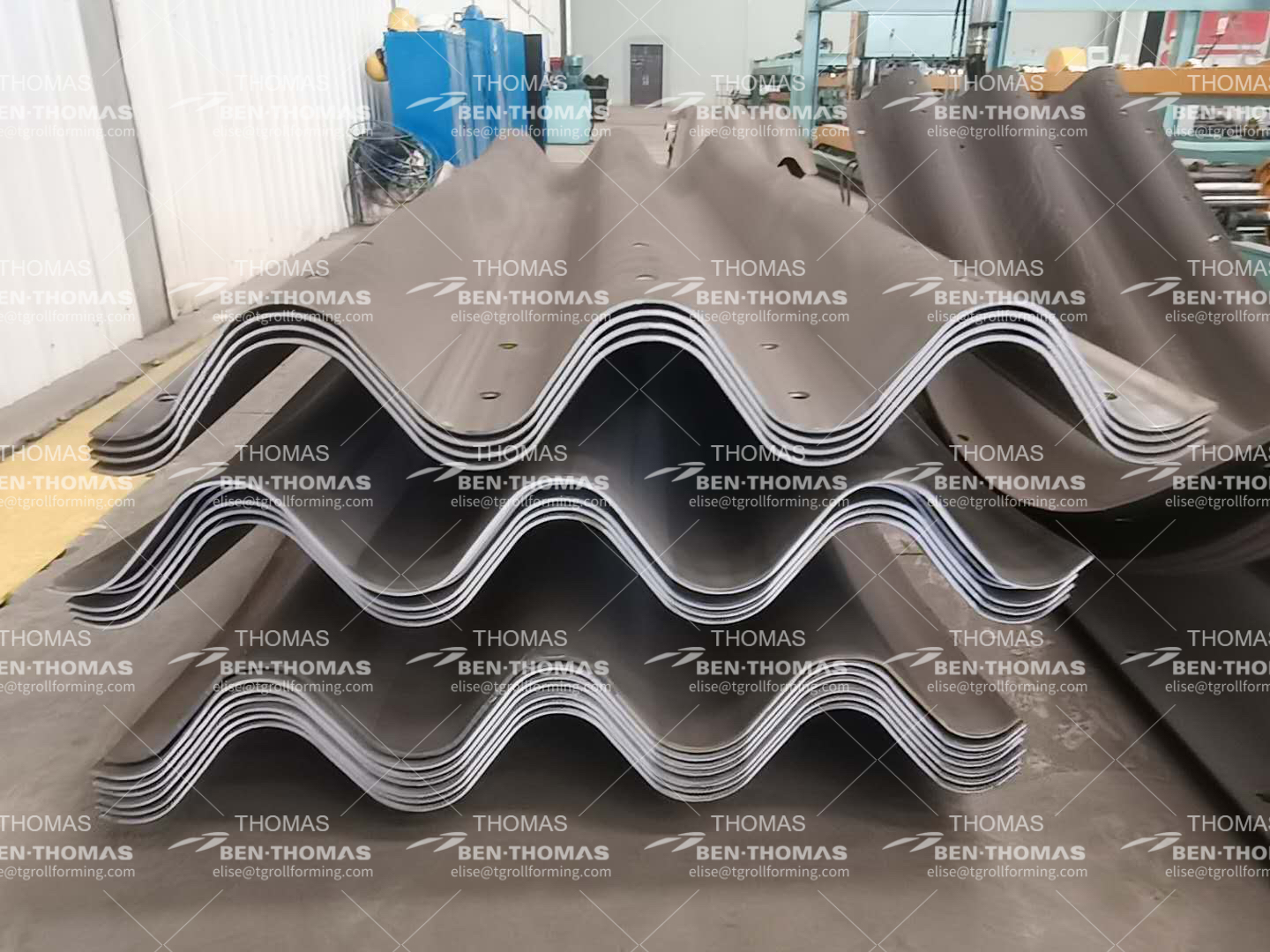

Ben-Thomas Machinery is proud to highlight our cutting-edge Long span culvert plate production line, specifically engineered for manufacturing deep-corrugated and super-corrugated steel plates. This heavy-duty system is ideal for customers in large-span bridge construction and tunnel projects, delivering high-strength structural plates for assembled soil-steel composite structures.

Capable of processing steel plates up to 10mm thick, this long span culvert corrugation plate equipment produces robust deep-wave plates that enable spans exceeding 20 meters, offering a cost-effective alternative to traditional concrete bridges and tunnels.

Core Features of the steel bridges corrugated plates mill:

The fully automated system integrates three primary sections:

- Corrugation Forming → Creates deep structural waves for exceptional load-bearing capacity.

- Precision Punching → Bolt holes positioned flexibly via PLC control, based on customer drawings for accurate assembly.

- Arc Bending/Curving → Shapes plates into arched segments for seamless on-site bolting.

High automation ensures superior precision, efficiency, and consistency, with customizable options for various corrugation profiles and galvanization levels.

Targeted Applications

This steel bridges corrugated plates equipment serves manufacturers and contractors focused on:

- Large-span buried bridges and grade separations ;

- Tunnel portals and underground passages ;

- Flood control arches and stormwater management structures ;

Ben-Thomas continues to innovate in machinery technology, providing reliable solutions for global road and bridge infrastructure development.

Contact us today for customized quotations or technical details on our corrugated plate production line for metal Bridges and culverts.

Email: elise@tgrollforming.com

WhatsApp/Tel: +86-15532817581