BEN-THOMAS Multi-Plate Assembled Culvert Production Line: Versatile Solutions for Diverse Infrastructure Applications

News 2025-12-20

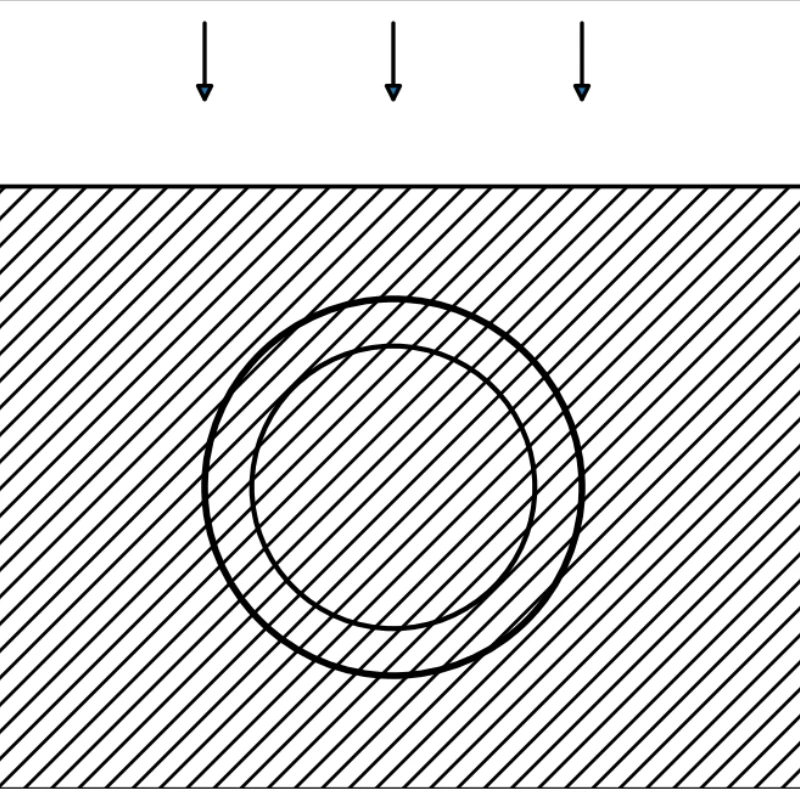

Ben-Thomas’s Corrugated Metal Pipes Machine Production Line for Drainage Structures has become a preferred choice for manufacturers worldwide, thanks to its exceptional versatility in producing high-strength, deep-corrugated plates for bolted assembly structures. This advanced manufacturing system enables the creation of large-span, durable culverts and bridges tailored to a wide range of challenging engineering applications.

BEN-THOMAS corrugated plate production line for short span bridges are fully customizable, supporting different corrugation profiles, various plate thicknesses up to 10mm, automated punching for drilling holes and a smart curving for precision fit. The BEN-THOMAS Corrugated Bridge-Plate processing equipment is not just a set of equipment, but a modular infrastructure manufacturing engine with precise design, high integration and intelligent control, achieving a revolutionary leap from raw materials to finished components.

Core of Precision Manufacturing:

– Fully automated production line for buried arch bridge system:

The core of the production line for corrugated steel drainage structures is a fully servo-controlled continuous corrugation profiling section, employing a multi-pass progressive forming process to ensure the steel plate maintains optimal metal flow structure during cold rolling. It can process high-strength steel up to 10mm thick with extremely high forming precision.

Manually Adjustable Plate Thickness: The production line can use different plate thicknesses via power adjustment, freeing up manual labor.

Online Stress Relief Device: Tension leveling is performed simultaneously during forming to eliminate internal stress, ensuring the straightness and flatness of the plate, laying the foundation for subsequent precise splicing.

– Punching unit: a smart drilling device

The formed corrugated plate enters the heavy-duty drilling center, which integrates high-precision punching and flexible punching functions.

– Hydraulic bending workstation:

Continuous bending to achieve the radius required by the drawing.

Key Applications of Multi-Plate Assembled Culverts:

The structures produced by BEN-THOMAS Corrugated culvert plate forming machine for Rail underpasses excel in the following scenarios:

Highway and Railway Culverts & Grade Separations → Ideal for large drainage channels under roads or railways, minimizing traffic disruption during installation.

Short-to-Medium Span Buried Bridges → Cost-effective alternatives to concrete bridges, supporting heavy vehicle and rail loads in rural or secondary routes.

Stormwater Management and Flood Control → Large-span arches maintain natural water flow while providing robust flood relief structures.

Wildlife and Ecological Crossings → Environmentally friendly passages that reduce habitat fragmentation caused by infrastructure.

Mining Tunnels and Conveyor Covers → Durable portals and protective enclosures in harsh industrial environments.

Low-Headroom Box Culverts → Rectangular configurations for sites with height restrictions, offering superior hydraulic performance.

BEN-THOMAS corrugated bridge-plate processing equipment is not just a product, but an engineering solution driving the transformation of the world’s road and bridge infrastructure towards efficiency, modularity, and sustainability. Whether dealing with harsh natural environments or meeting tight deadlines, its reliable performance and excellent adaptability make it a key partner for your project’s success.

Contact us today to explore how our production line can support your infrastructure projects.

Tel: +86-155 3281 7581

Email: elise@tgrfm.cn