Revolutionizing Infrastructure: Advanced Corrugated Steel Utility Tunnel Production Line Unveiled

News 2025-12-27

Advanced Automated Production Line for Corrugated Steel Utility Tunnels— Engineered for Efficient, Large-Scale Underground Pipeline Networks

FOR IMMEDIATE RELEASE

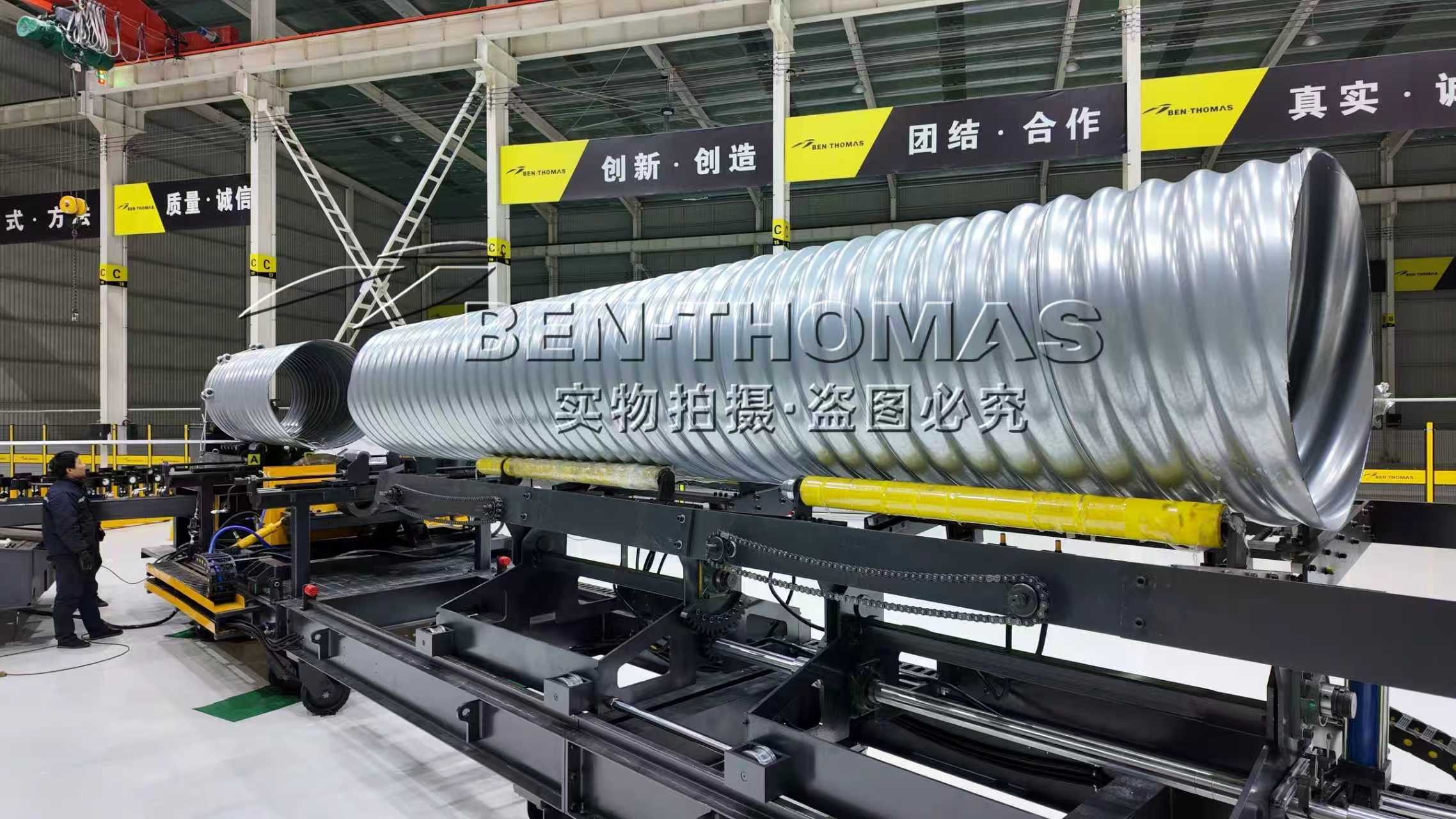

The future of efficient and resilient utility infrastructure is here with the launch of our state-of-the-art Corrugated Steel Utility Tunnel manufacturing line. This fully integrated system represents a quantum leap in the production of prefabricated tunnel sections, designed to meet the soaring global demand for durable underground conduits for power, data, water, and drainage systems.

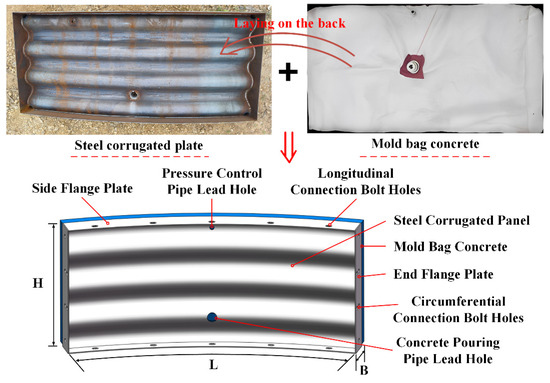

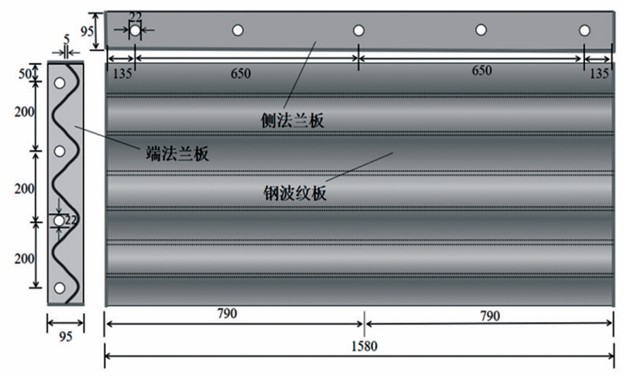

At the heart of this innovation is our flagship Corrugated Steel Utility Tunnel forming machinery. Engineered for precision and speed, this robust machine utilizes advanced roll-forming technology to transform high-strength steel coils into deep-corrugated panels with unparalleled consistency. The corrugated design is not merely aesthetic; it provides exceptional structural rigidity, allowing the tunnels to withstand heavy backfill loads and harsh environmental conditions while optimizing material usage.

“Our new Production line for Corrugated Steel Utility Tunnel is a game-changer,” said Ben, Chief Engineer at BenThomas. “We’ve moved beyond standalone machines to a seamless, automated process. From coil feeding and precision corrugation to cutting, curving, and finishing, every stage is integrated. This ensures maximum throughput and product quality, enabling contractors and governments to expedite large-scale utility projects with reliable, long-lasting solutions.”

The complete Corrugated Steel Utility Tunnel making machine system offers significant advantages:

· High-Speed Production: Automated workflows drastically reduce manufacturing time for large-diameter tunnels.

· Superior Strength-to-Weight Ratio: The produced tunnels are easier to transport and install than concrete alternatives, slashing project timelines and costs.

· Corrosion Resistance: Lines can be configured to process pre-coated steels (like aluminized or galvanized) for extended service life.

· Design Flexibility: The machinery can be tailored to produce a wide range of diameters and profiles to meet specific project specifications.

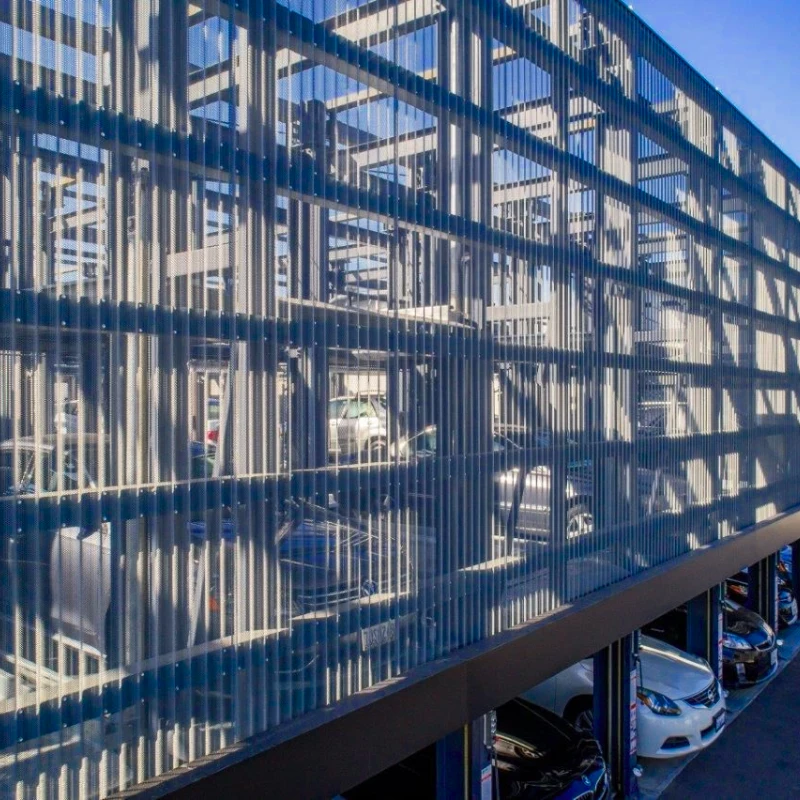

This comprehensive production solution is ideally suited for urban development projects, industrial park construction, and renewable energy installations where organizing and protecting utility networks is critical. By providing a faster, stronger, and more economical alternative to traditional methods, this advanced manufacturing line is set to become the global standard for utility tunnel fabrication.

About BenThomas:

BenThomas is a leading innovator in heavy-gauge metal forming technology. We specialize in designing and building custom machinery and production lines for critical infrastructure components, including corrugated steel structures for arches, bridges, culverts, and utility tunnels. Our commitment is to empower builders worldwide with engineering excellence.

For more information on our Corrugated Steel Utility Tunnel forming machinery and complete manufacturing solutions, visit our website or contact our sales team.

Production line mainly contains :

– Corrugation Profiling ;

– Punching system ;

– Bending system ;

Contact: Elise Lee

Tel: +86-155 3281 7581

What’s App: +86-155 3281 7581

WeChat: +86-155 3281 7581

Email: elise@tgrollforming.com