Innovative Multi-Plate Culvert Structure Production Line

News 2021-07-13

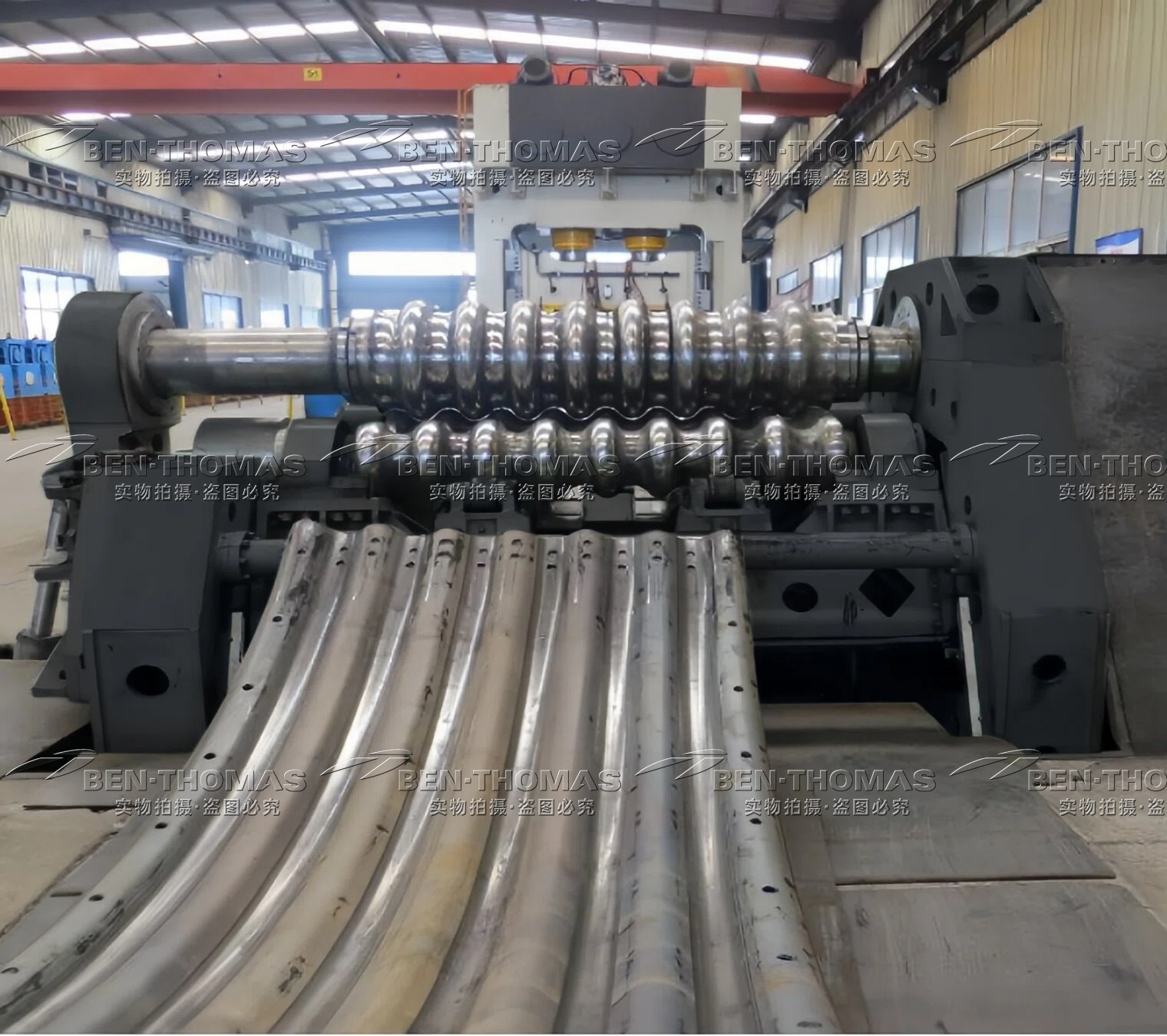

Our newly launched Multi-Plate Culvert Structure Production Line integrates corrugating forming, intelligent punching, and high-precision bending into a fully automated process, specifically designed for the production of high-strength, high-precision multi-plate corrugated culvert structures. This Corrugated Steel Pipe Culvert machine significantly improves the manufacturing efficiency and product quality of metal corrugated culverts, meeting the growing demand for high-performance prefabricated structures in modern large-scale drainage, transportation, and water conservancy projects. This assembled corrugated steel pipe manufacturer line represents a significant leap forward in metal corrugated structure manufacturing technology, focusing on the efficient and precise production of multi-plate corrugated steel structure units for assembling large drainage culverts, passageways, and bridges.

This corrugated section steel plate production line is not a simple assembly line, but a complete Drainage Culvert Pipe machine solution integrating three core manufacturing processes:

- Precision Corrugation Shaping: The first section of the production line is a high-performance corrugation shaping unit, which continuously and precisely rolls flat steel coils into the corrugated cross-section required by the design. This process ensures that each corrugated sheet has excellent structural strength and drainage efficiency, forming the basis for corrugated steel box culverts and metal corrugated culvert pipes.

- Intelligent Punching: The subsequent punching station is equipped with an advanced flexible punching system. It can process holes for subsequent bolt connections on the formed corrugated sheet at high speed and high precision, according to engineering design requirements. This ensures that the sheets are perfectly aligned and fastened during the assembly of Culvert Pipes, achieving structural integrity and sealing.

- High-Precision Sheet Bending: The final bending unit uses servo control technology to precisely bend the perforated corrugated sheet in three dimensions to form the required arc or special angle for the culvert. This crucial step enables the production line to flexibly manufacture components of various sizes and radii of curvature, adapting to a wide range of designs from steel culvert pipes to complex box culverts.

By investing in BEN THOMOAS’s advanced multi-plate culvert pipe machine, manufacturers can not only significantly improve production capacity and product consistency, but also gain an advantage in the highly competitive infrastructure market by leveraging the superior performance of its structural components in terms of compressive strength, corrosion resistance and service life.

Contact: Elise Lee

Tel: +86-155 3281 7581

What’s App: +86-155 3281 7581

WeChat: +86-155 3281 7581

Email: elise@tgrollforming.com