BEN-THOMAS Revolutionizes Infrastructure with High-Precision Production Line for Multi Plate Corrugated Tunnel Structure

News 2026-01-19

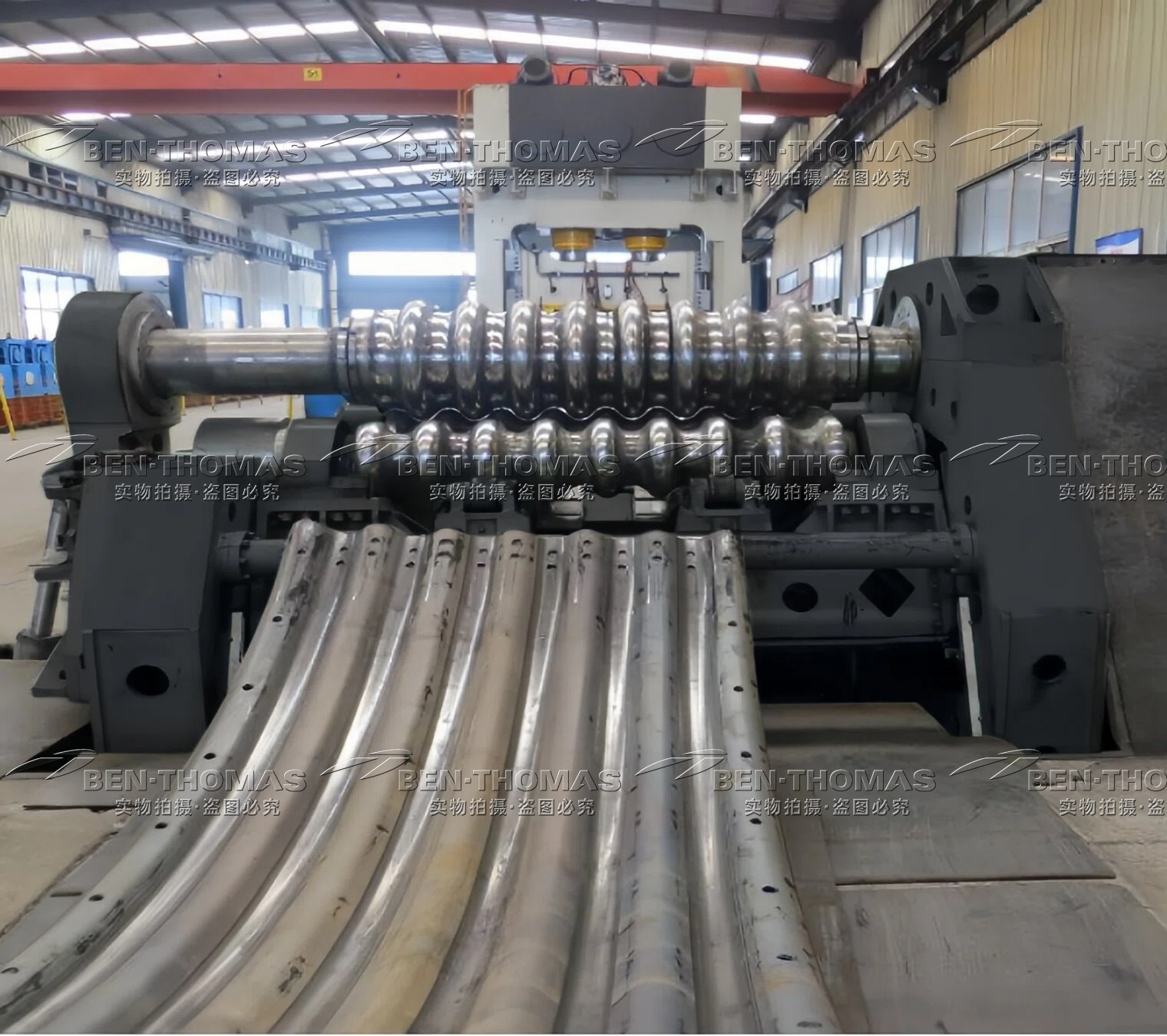

Machine to make segmental corrugated steel plate

Contact: Elise Lee

Tel: +86-155 3281 7581

Email: elise@tgrfm.cn

In the global infrastructure and civil engineering sector, the demand for durable, high-quality drainage solutions is soaring. Leading the charge is BEN-THOMAS, a specialized manufacturer that has dedicated decades to the perfection of a single craft: the Steel Corrugated Steel Culvert Pipe Manufacturing Equipment.

By focusing exclusively on the R&D and construction of Multi Plate Culvert Pipe Arch Assembly Making Machine, BEN-THOMAS has earned a prestigious reputation among international clients for reliability, precision, and technological innovation.

What is a Production line for Multi Plate Culvert Pipe Arch Assembly?

A corrugated steel pipe (CSP) machine is a specialized industrial production line designed to transform flat steel sheets into reinforced, corrugated structures. These pipes are essential for modern infrastructure, used extensively in highway culverts, municipal drainage, bridge reinforcements, and underground tunnels due to their superior load-bearing capacity and flexibility compared to traditional concrete.

A Comprehensive Three-Stage Production Process :

The BEN-THOMAS Production Line for corrugated steel arch culvert for tunnel is engineered for seamless integration, consisting of three core technical stages:

- Corrugation Plate Profiling: The initial stage where flat steel is fed through a series of high-precision rollers to create the specific wave profile (corrugation) that gives the pipe its structural strength.

- Punching (Perforation): An automated system that creates precise bolt holes or drainage perforations required for assembly and installation.

- Curving (Bending): The final stage where the corrugated plates are curved to the exact radius required to form circular or arched culvert sections.

Why Choose BEN-THOMAS? Key Features and Advantages

The BEN-THOMAS production line for multi plate animal underpass tunnel is designed to maximize ROI for manufacturers through four distinct pillars of excellence:

- Fully Automated Production: The entire metal corrugated culvert pipe line operates without the need for manual intervention, reducing labor costs and eliminating human error.

- High Efficiency: Optimized for high-speed output, ensuring that large-scale infrastructure projects stay ahead of schedule.

- Low Scrap Rate: Advanced material handling and precision engineering ensure that raw material waste is kept to an absolute minimum.

- Superior Accuracy: The terminal profiles produced feature industry-leading precision, ensuring perfect fitment and structural integrity during field installation.

As global demand for resilient infrastructure grows, BEN-THOMAS continues to set the standard for corrugated steel culvert drainage pipe manufacturing machine, providing the tools necessary to build a more durable world.

For more detail , please contact with our sales team :

Contact: Elise

Tel: +86-155 3281 7581

Email : elise@tgrfm.cn