BEN-THOMAS Unveils Advanced SteelCor Corrugated Steel Pipe Production Line: Precision-Engineered Production Line for High-Performance Culvert Pipes

News 2026-01-19

metal box culvert structure production line

Contact: Elise Lee

Tel: +86-155 3281 7581

Email: elise@tgrfm.cn

BEN-THOMAS , a leading multi-plate culvert pipe equipment manufacturer worldwide, continues to set industry benchmarks with its specialized SteelCor Corrugated Steel Culvert Pipe Forming Machine and full Production Line for SteelCor Corrugated Steel Plate Structure. With decades of exclusive focus on metal corrugated culvert pipe equipment, BEN-THOMAS has delivered over 100 successful projects worldwide, earning exceptional praise from global clients for reliability, customization, and superior performance.

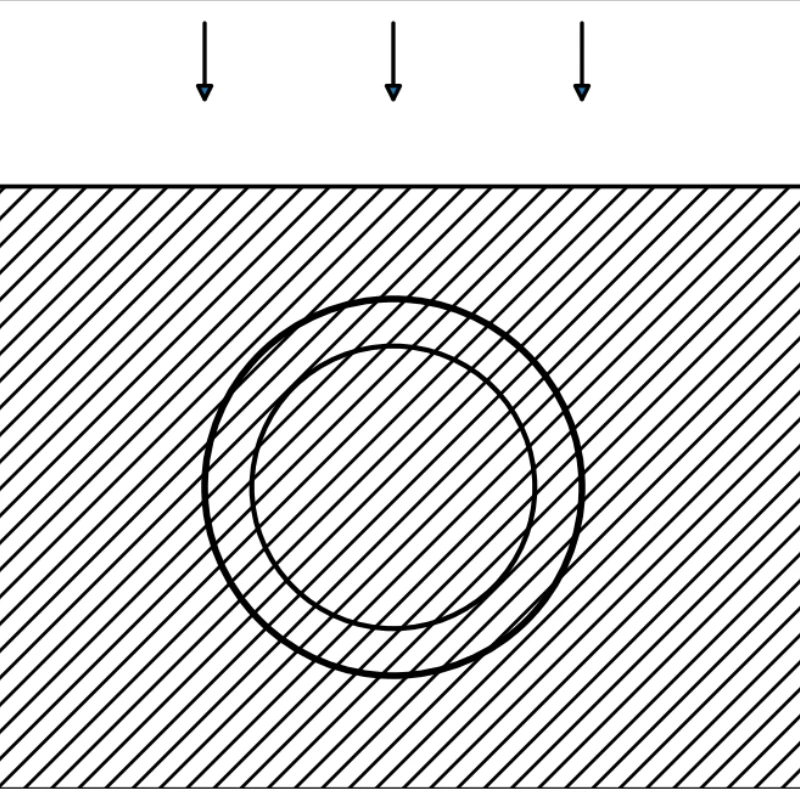

The SteelCor Corrugated Steel Pipe (also known as steel corrugated culvert pipes) is a durable, lightweight, and flexible drainage solution widely used in civil engineering. These galvanized or coated steel structures provide excellent corrosion resistance and structural integrity, making them ideal for highway drainage, railway culverts, storm sewers, small bridges, tunnels, retaining walls, underpasses, wildlife passages, and mining support applications.

Production line for Corrugated Metal Pipes for Culverts and Sewers

Contact: Elise Lee

Tel: +86-155 3281 7581

Email: elise@tgrfm.cn

BEN-THOMAS’s steel corrugated culvert pipes making machine is a fully integrated, high-end production line designed to transform steel coils into precision-shaped corrugated plates ready for assembly into culvert pipes. The core Culvert Corrugated Plate Manufacturing Machine process consists of three essential parts:

- Corrugated Plate Shaping — Advanced rolling technology shapes flat steel coils into precise corrugation profiles , ensuring consistent wave patterns for optimal strength and hydraulic performance.

- Perforation (Punching) — Hydraulic systems accurately punch bolt holes and other required openings in the corrugated plates, facilitating easy on-site assembly.

- Bending (Arc Bending) — Specialized bending units curve the formed plates into the required radii, enabling the creation of round, arch, or elliptical culvert shapes tailored to project specifications.

What sets BEN-THOMAS’s Production Line for Corrugated Steel Arch Culvert apart is its cutting-edge automation and efficiency:

- Fully Automatic Operation — The entire production line for multiplate structures culvert pipe runs with minimal to no manual intervention, thanks to PLC control systems and synchronized hydraulic components.

- High Efficiency — Designed for continuous, high-speed production to maximize output and reduce operational costs.

- Low Scrap Rate — Precision engineering and robust quality controls minimize material waste.

- High Precision of Finished Profiles — Delivers exceptional dimensional accuracy, ensuring perfect fit during assembly and superior performance in demanding infrastructure projects.

For inquiries about the manufacturing line for culvert corrugated steel buried structures, custom corrugation profiles, or complete production solutions, contact the BEN-THOMAS international sales team today.

Contact: Elise

Tel:+86-155 3281 7581

Email: elise@tgrfm.cn