BENTHOMAS Unveils Its Latest High-Efficiency Helical Corrugated Steel Pipe Mill, Setting a New Standard in Metal Spiral Corrugated Pipe Manufacturing

News 2025-12-13

BENTHOMAS Unveils Its Latest High-Efficiency Helical Corrugated Steel Pipe Mill, Setting a New Standard in Metal Spiral Corrugated Pipe Manufacturing

In response to the accelerating global demand for resilient and sustainable drainage and conveyance solutions, BENTHOMAS Machinery is proud to announce significant advancements in its flagship production technology: the next-generation Helically Wound Corrugated Steel Pipe Machinery. This innovation underscores our commitment to equipping manufacturers worldwide with the tools to build the critical infrastructure of tomorrow.

The global market for corrugated steel pipes is expanding rapidly, driven by large-scale investments in transportation, urban drainage, and renewable energy projects. Traditional pipe manufacturing methods often struggle to meet the dual demands of high-volume output and stringent quality standards. The industry is now shifting decisively toward highly automated, continuous spiral forming systems, which offer unparalleled flexibility, strength consistency, and material efficiency.

The Engineering Leap: BENTHOMAS’s Integrated Production Line

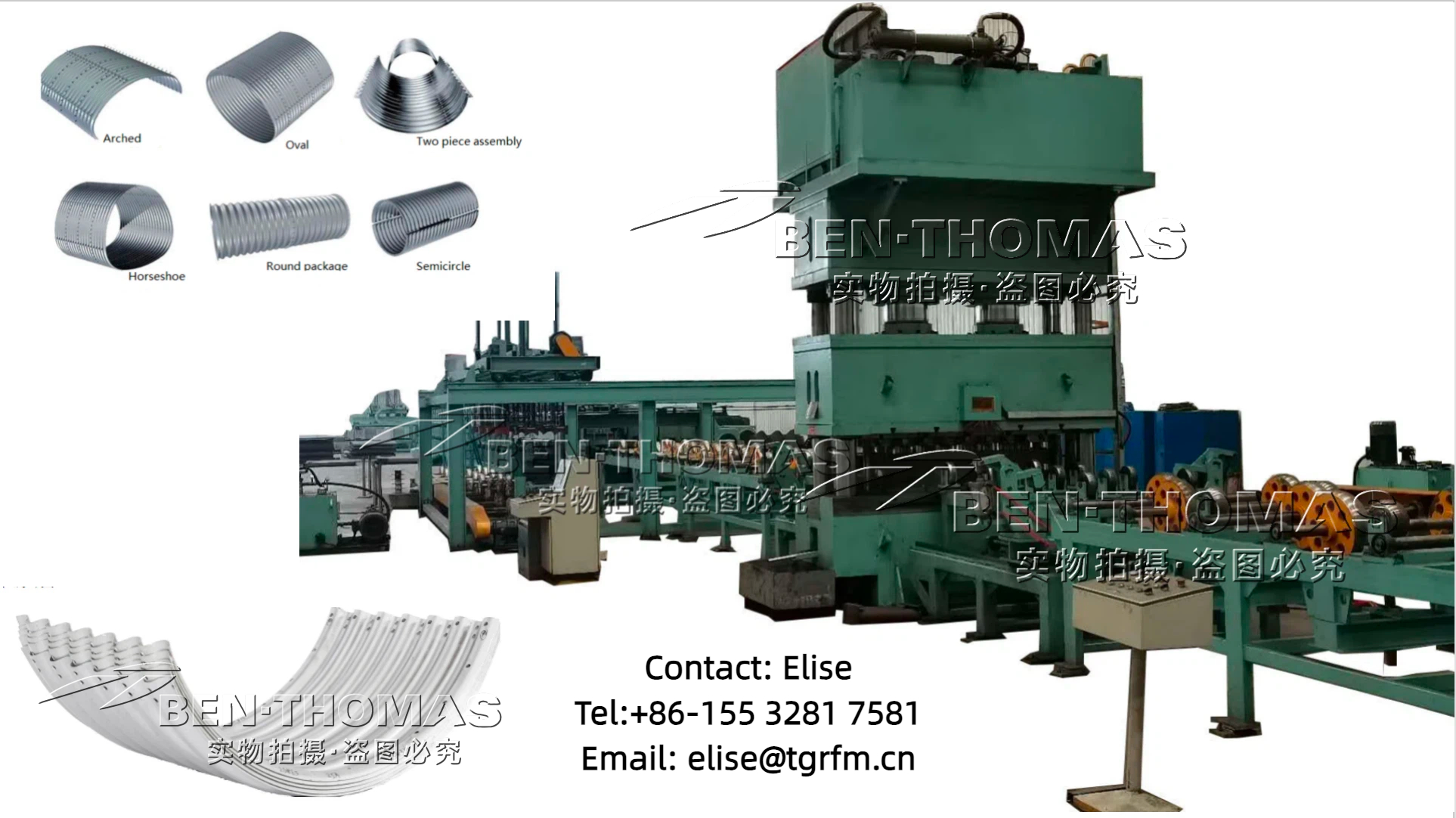

At the heart of this shift is BENTHOMAS’s fully integrated Helibore Corrugated Pipe Machine Production Line. This system represents a synthesis of precision engineering and intelligent automation, designed to produce superior-quality pipes with diameters ranging from 500mm to over 3000mm. The “Helibore” nomenclature reflects its core capability: a continuous helical boring and forming process that ensures seamless, monolithic pipe structure.

Key innovations of the production line include:

1. Intelligent Synchronized Forming: Our advanced Helical Corrugated Steel Pipe Mill features a digitally synchronized system where corrugation profiling and spiral winding are perfectly coordinated by a central PLC. This eliminates dimensional variances and ensures every meter of pipe meets exact geometric and tolerance specifications.

2. Patented Lock-Seam Technology: The Metal Spiral Corrugated Pipe Mill incorporates a proprietary lock-seaming mechanism. This creates a continuous, watertight, and structurally integral helical seam that is stronger than the base material itself, crucial for withstanding high backfill loads and hydraulic pressure.

3. Rapid, Tool-Free Diameter Adjustment: A major bottleneck in traditional production is diameter changeover. The Helically Wound Corrugated Steel Pipe Machinery from BENTHOMAS allows for quick diameter adjustments through programmable logic, dramatically reducing downtime and enabling cost-effective small-batch production.

4. End-to-End Automation: From coil loading to final cut-off and stacking, the Helibore Corrugated Pipe Machine Production Line minimizes manual intervention. This results in consistent product quality, enhanced worker safety, and a significantly higher output rate compared to semi-automatic systems.

Driving Sustainability and Cost-Efficiency

This new generation of machinery supports sustainable manufacturing in two key ways: First, its high material yield minimizes steel waste. Second, the production of long-length, lightweight yet high-strength pipes reduces transportation carbon footprint and onsite installation time for end-clients. For the pipe manufacturer, this translates into a lower cost-per-meter and a stronger competitive edge in bidding for international infrastructure tenders.

Industry Impact and Availability

BENTHOMAS’s latest line is already being commissioned by leading manufacturers in Southeast Asia and the Middle East, where it is being used to produce pipes for major highway drainage and land reclamation projects. “Our goal is to provide our partners with not just machinery, but a definitive productivity advantage,” said Chief Engineer at BENTHOMAS. “This Helical Corrugated Steel Pipe Mill is engineered to be the most reliable and profitable asset in their production facility.”

About BENTHOMAS

BENTHOMAS is a globally recognized leader in the design and manufacturing of high-performance spiral pipe production lines. With decades of engineering expertise, we provide turnkey solutions that empower metal fabricators to serve the construction, infrastructure, and utility sectors with superior products.

For more information on our Metal Spiral Corrugated Pipe Mill, Helically Wound Corrugated Steel Pipe Machinery, or the complete Helibore Corrugated Pipe Machine Production Line, please visit our website at cmpbt.com or contact our international sales team directly.

Contact: Elise Lee

Tel: +86-155 3281 7581

What’s App: +86-155 3281 7581

WeChat: +86-155 3281 7581

Email: elise@tgrollforming.com