What Is the Advantage of Corrugated Pipe?

News 2026-01-19

Why Corrugated Pipe Keeps Solving Underground Failures

Buried pipe failures follow a familiar pattern. Installation looks fine. Backfill settles. Traffic loads repeat. After the first winter, deformation shows up and flow drops.

That’s where smooth-wall pipe often reaches its limit. Corrugated pipe is designed to prevent that failure chain by carrying external load and absorbing ground movement long after the trench is closed.

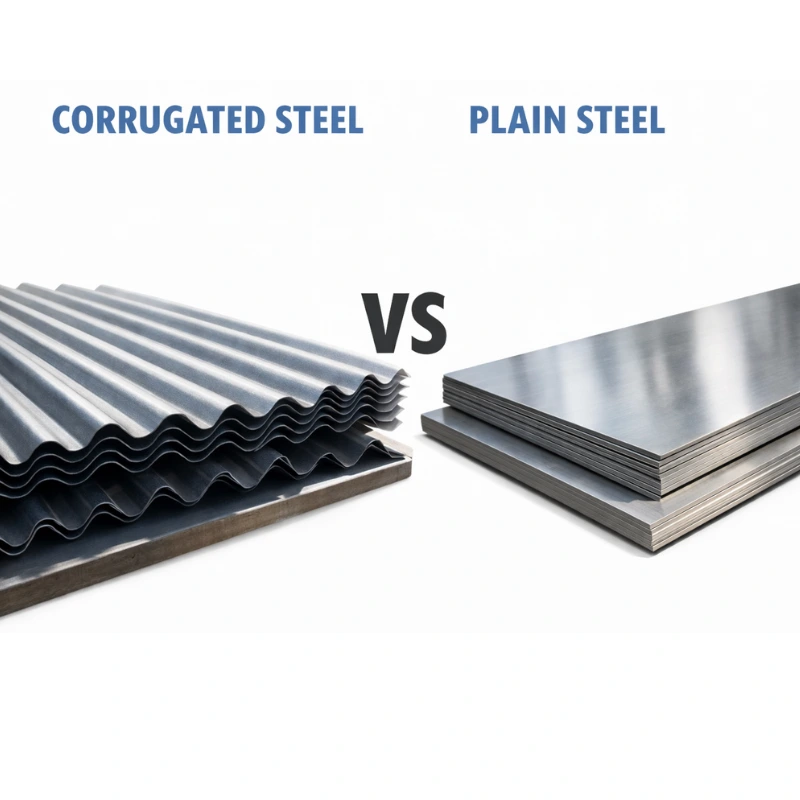

What Makes a Pipe Corrugated and Load-Bearing

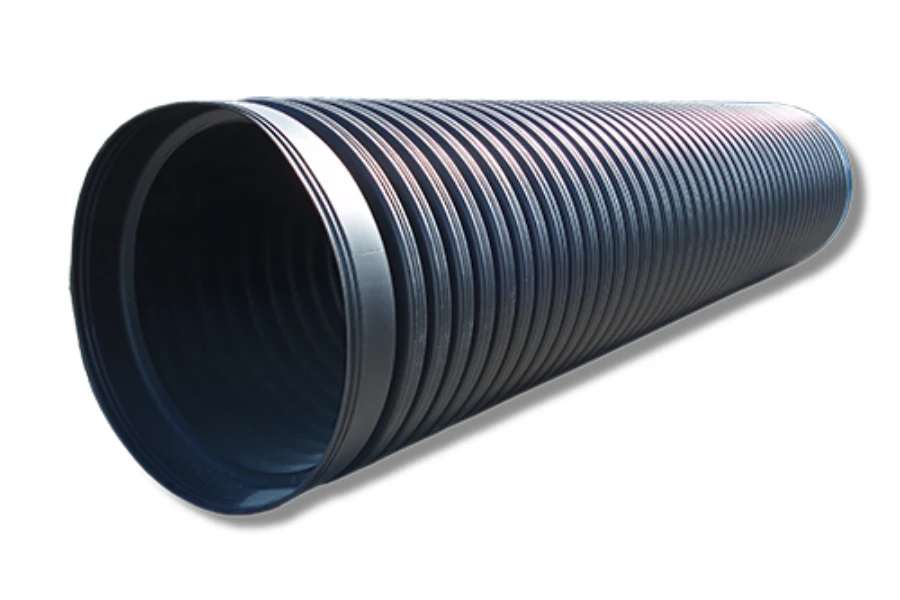

Corrugated pipe structure showing ridges and valleys designed for load bearing

A corrugated pipe uses repeating ridges and valleys along the outer wall. That geometry controls how external load travels through the pipe instead of concentrating stress in one area.

Common configurations include:

-

Single-wall corrugated pipe, where the profile provides structure.

-

Double-wall corrugated pipe, with a corrugated exterior and a smooth inner wall.

Materials vary by environment, but the principle stays the same. Shape governs underground performance.

1. Built to Carry Soil and Traffic Load Without Crushing

Corrugated pipe resisting soil pressure and traffic loads in buried installation

Buried pipes fail from external load, not internal pressure.

Corrugation increases ring stiffness, allowing the pipe to resist:

-

Soil pressure.

-

Repeated vehicle loads.

-

Backfill compaction forces.

Smooth pipe loses stiffness once deformation begins. Corrugated pipe spreads load around the circumference, delaying that failure point.

Takeaway: higher load capacity without thicker, heavier walls.

2. Stronger Pipe Without Adding Thickness or Weight

Specifying thicker pipe raises cost and handling issues without addressing the core problem.

Corrugated pipe gains stiffness through geometry, not added material. This results in:

-

Lower material use.

-

Reduced weight.

-

A better strength-to-weight balance.

Projects meet structural demands without paying for unnecessary mass.

3. Flexes With the Ground Instead of Cracking Under It

Rigid pipes crack when the ground moves, especially in soft soils and freeze-thaw zones.

Corrugated pipe allows controlled deflection. It accommodates minor settlement and distributes stress instead of concentrating it at one point.

Field result: systems that flex slightly tend to outlast rigid ones.

4. Easier to Handle, Faster to Install, Fewer Site Headaches

Many underground issues start during installation.

Corrugated pipe is lighter, easier to align, and more forgiving during backfill. Crews spend less time fighting the material and more time getting bedding and grade right, reducing rework and callbacks.

5. Strength on the Outside, Smooth Flow on the Inside

Double wall corrugated pipe with smooth inner wall for efficient drainage flow

Drainage systems still depend on flow performance.

That’s why many corrugated designs use:

-

A corrugated outer wall for load.

-

A smooth inner wall for reduced hydraulic resistance.

This keeps flow predictable without sacrificing structural reliability.

6. Decades of Service Life When Material Matches the Site

Service life depends on material selection and environment.

With options like galvanized or aluminized steel and corrosion-resistant plastics such as HDPE, corrugated pipe regularly delivers decades of service. The corrugated profile also distributes stress evenly, slowing fatigue and localized wear.

Longevity comes from correct selection, not overdesign.

Where Corrugated Pipe Makes Sense in Real Projects

Corrugated pipe adapts well to varied site conditions, making it suitable for:

-

Municipal and highway drainage.

-

Culverts and road crossings.

-

Agricultural drainage.

-

Utility and cable protection.

-

Industrial infrastructure.

It performs where conditions are less than ideal.

Why Corrugated Pipe Keeps Winning in Buried Applications

Corrugated pipe succeeds because it uses structure intelligently, not because it uses more material.

Its advantages come down to:

-

Reliable performance under external load.

-

Efficient material use.

-

Flexibility that reduces failure risk.

-

Faster, more forgiving installation.

-

Proven durability underground.

Manufacturers focused on corrugated metal pipe systems understand these trade-offs at a system level. Ben-Thomas designs complete corrugated metal pipe production lines around these same principles because they hold up in long-term infrastructure use.

The Real Advantage Comes From Shape, Not More Material

The advantage of corrugated pipe isn’t thicker walls or marketing claims. It’s geometry doing the work.

By combining load capacity, controlled flexibility, and material efficiency, corrugated pipe addresses the failures buried systems face over time. Equipment helps produce it, but sound engineering decisions are what keep pipes working long after installation.

FAQ

What is the main advantage of corrugated pipe compared to smooth pipe?

The main advantage lies in how corrugated pipe handles external load. Its ribbed profile increases ring stiffness, allowing the pipe to resist soil pressure and traffic loads more effectively than smooth pipe with similar wall thickness. This geometry-driven strength reduces deformation risk in buried installations.

Are corrugated pipes strong enough for buried applications?

Yes. Corrugated pipes are designed specifically for buried conditions. Their structure distributes external loads evenly around the pipe wall, making them suitable for drainage systems, culverts, and road crossings when properly specified, installed, and supported by correct bedding and backfill.

Do corrugated pipes have lower flow efficiency?

Not necessarily. Many corrugated pipe systems use a smooth inner wall combined with a corrugated outer wall. This design maintains low hydraulic resistance while providing the structural strength needed for buried applications, allowing efficient flow without sacrificing load-bearing performance.

Are corrugated pipes flexible or rigid?

Corrugated pipes are semi-flexible. This controlled flexibility allows them to accommodate minor soil movement and settlement without cracking. Compared to rigid pipe systems, this behavior reduces stress concentration and lowers the risk of long-term structural failure in unstable ground conditions.

How long does corrugated pipe typically last?

Service life depends on material selection and environmental conditions. Corrugated steel and HDPE pipes can provide several decades of service when properly coated, installed, and maintained. In many infrastructure applications, service life commonly exceeds 50 years under normal operating conditions.