Culvert corrugated steel plate mill

Production line mainly contains :

– Corrugation Profiling ;

– Punching system ;

– Bending system ;

Contact: Elise Lee

Tel: +86-155 3281 7581

What’s App: +86-155 3281 7581

WeChat: +86-155 3281 7581

Email: elise@tgrollforming.com

Product Details

Advanced Steel Bridge & Culvert Corrugated Plate Manufacturing Equipment

Comprehensive Production Solutions for Modern Infrastructure

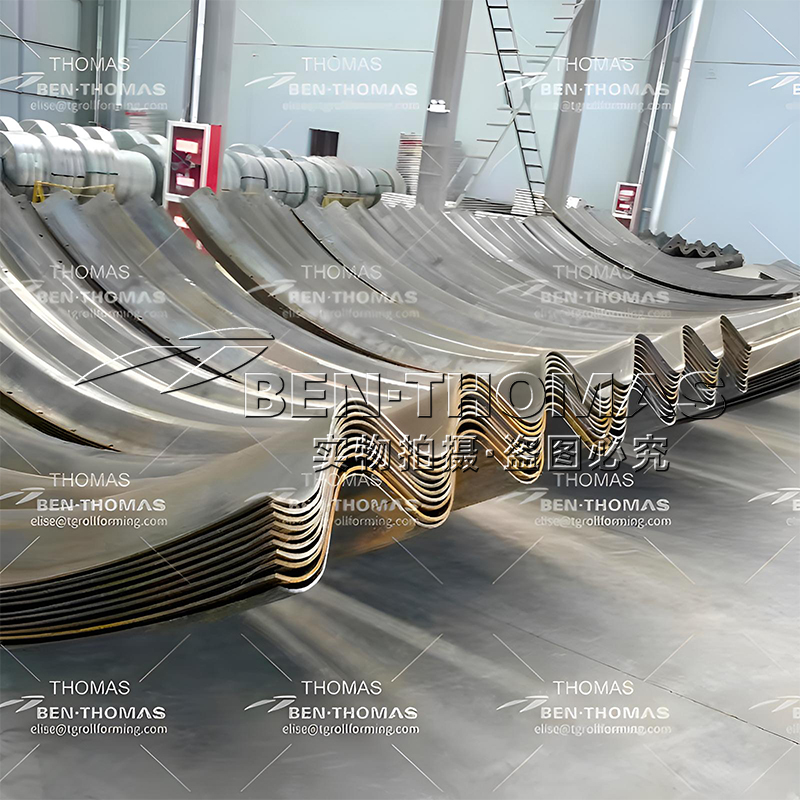

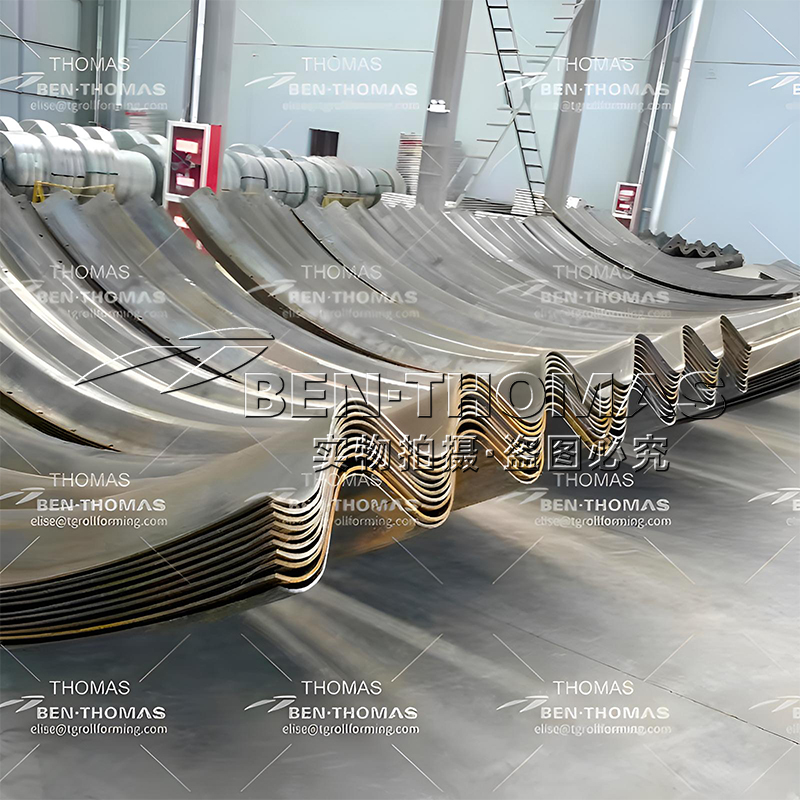

In the realm of modern infrastructure, corrugated steel plates are critical components, prized for their exceptional strength, durability, and cost-effectiveness in applications ranging from steel bridges to drainage culverts. Meeting the exacting demands of global construction standards requires precision-engineered manufacturing systems. Our company provides a complete suite of high-performance equipment designed to transform raw steel into high-quality finished products efficiently and reliably.

Core Product Line: The Culvert Corrugated Steel Plate Mill

At the heart of our offering is the state-of-the-art Culvert Corrugated Steel Plate Mill. This specialized rolling mill is engineered to form precise, consistent corrugation profiles into steel coils or sheets. Key features include:

· High-Precision Roll Forming: Utilizes hardened, CNC-machined rolls to ensure accurate corrugation geometry (such as 150×50, 380×140 mm profiles) critical for structural integrity.

· Robust Construction: Built with heavy-duty frames and drives to handle high-tensile steels with stability, minimizing deflection during operation.

· Adjustable Flexibility: Quick-change roll systems allow for producing various corrugation depths and pitches on a single mill, enhancing versatility.

· Integrated Control Systems: Advanced PLC and HMI interfaces enable precise control over speed, feed, and forming pressure, guaranteeing repeatable quality.

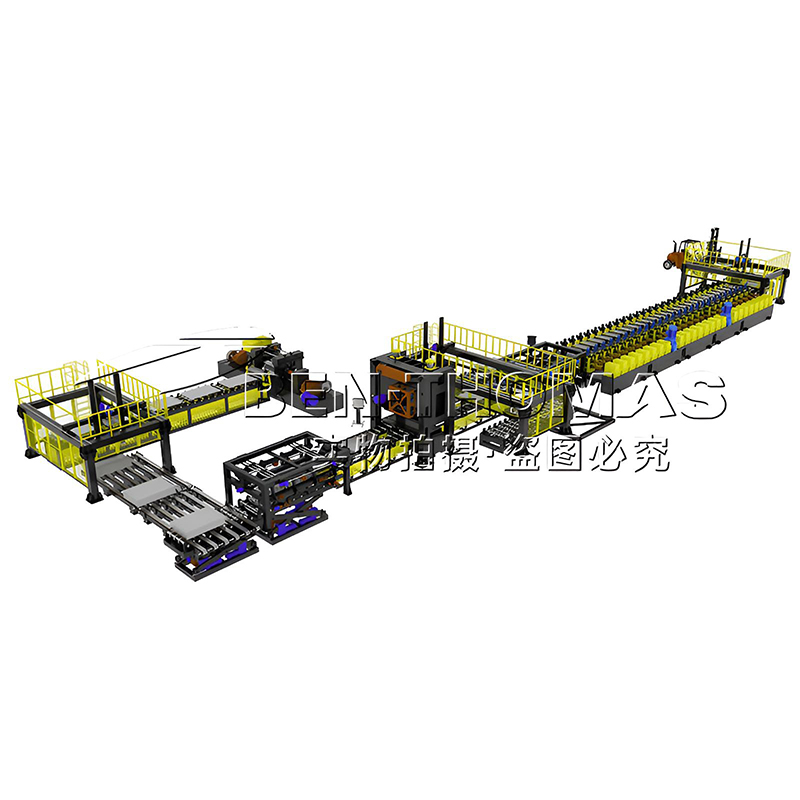

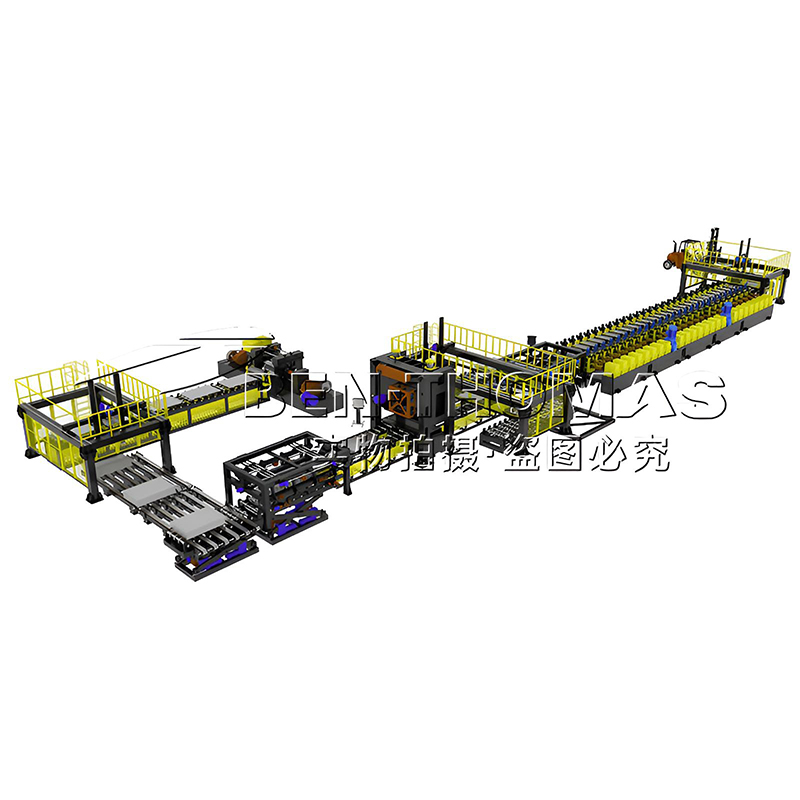

The Complete Culvert Corrugated Steel Plate Equipment Package

Beyond the core mill, a fully optimized production line requires integrated supporting equipment. Our comprehensive Culvert Corrugated Steel Plate Equipment package includes:

· Decoiling & Feeding Systems: For smooth, controlled unwinding of steel coils.

· Pre-Piercing & Hole Punching Units: For creating bolt and service holes with high accuracy prior to or after forming.

· Cut-to-Length Systems: Flying shears or precision saws for cutting formed plates to exact customer lengths.

· Automated Stacking & Handling: Robotics or conveyor systems to organize finished plates for packaging and shipment, improving safety and throughput.

End-to-End Automation: The Culvert Corrugated Steel Plate Machine Production Line

For maximum productivity, we design and deliver fully integrated Culvert Corrugated Steel Plate Machine Production Lines. This turnkey solution seamlessly connects all individual machines into a synchronized, automated workflow.

1. Material Loading: Coil stock is loaded onto the decoiler.

2. Leveling & Feeding: Steel is straightened and fed into the mill.

3. Corrugation Forming: The plate passes through the Culvert Corrugated Steel Plate Mill to gain its structural profile.

4. Punching & Cutting: The formed sheet is precisely punched and cut to specified dimensions.

5. Output & Stacking: Finished plates are automatically stacked, ready for galvanization (if required) or direct shipment.

This continuous production line dramatically increases output, reduces labor costs, and ensures consistent, high-quality products for both culvert projects and steel bridge applications.

Technical Advantages & Applications

· High Efficiency & Output: Engineered for 24/7 operation with minimal downtime, meeting large-scale project demands.

· Superior Product Quality: Produces plates with excellent dimensional tolerance and surface quality, ensuring optimal fit and performance in the field.

· Material Savings: Precision forming minimizes scrap, optimizing material yield.

· Broad Application Range: The equipment produces plates ideal for:

· Steel Bridge Corrugated Plates: For bridge decks, arches, and structural elements.

· Multi-Plate Culverts: For drainage, underpasses, and small bridge structures.

· Tunnel Liners & Retaining Walls: For mining and civil engineering projects.

Why Choose Our Equipment?

We combine decades of engineering expertise with innovative technology to deliver robust, user-friendly, and future-proof manufacturing solutions. Whether you need a standalone Culvert Corrugated Steel Plate Mill or a complete automated Production Line, we provide comprehensive support from design and installation to training and after-sales service.

Invest in precision. Build with strength. Contact us today to discuss your corrugated steel plate production needs and request a detailed quotation.

Frequently Asked Questions

For the metal corrugated pipe production line ,We offer complete in-house tooling design and manufacturing to match your product profiles. After delivery, we provide installation supervision, operator training, and a warranty period. Remote troubleshooting, spare parts supply, and periodic maintenance guidance are also part of our long-term support package.

Yes, our Production Line for Culvert Structural Plate are engineered to process various materials including galvanized steel, aluminum, pre-painted coils, and stainless steel. Material thickness typically ranges from 1.5mm to 12.0mm for Multi Plate Corrugated Culvert Production Line and 1.5mm to 4.0mm for Corrugated Spiral Pipe Production Line. We customize the machine configuration—such as roller hardness, motor power, and control settings—to ensure precise forming and long tooling life for your chosen specification.

Our Multi Plate Corrugated Culvert Production Line and Corrugated Spiral Pipe Production Line feature high automation with integrated PLC control systems that manage speed, length cutting, welding (for pipe lines), and real-time monitoring. Automated sensors detect deviations, and the system can adjust parameters to maintain consistency. This minimizes manual intervention, reduces waste, and ensures each panel or pipe meets precise dimensional and structural standards.

The Spiral Corrugated Pipe Machine Output speed depends on pipe diameter, material thickness, corrugation profile, and welding method. Standard speeds range from 5 to 30 meters per minute. We optimize throughput by configuring heavy-duty decoilers, high-torque spiral forming units, and automated arc welding or seam locking systems—all tailored to your target production rate and product specifications.

We have extensive experience inglobal export packaging and shipping. Mobile Spiral Corrugated Pipe Mill is disassembled into modular, crate-protected sections. Critical components are shock-proof mounted and moisture-sealed. We provide full shipping documentation (packing list, commercial invoice, certificate of origin) and can arrange FOB, CIF, or DAP delivery based on your preference, working with reliable freight forwarders.

We offer a standard18-month warranty from the date of commissioning, covering defects in materials and workmanship for all major components (mainframe, motors, PLC, gearboxes). Consumable parts like forming rolls have a separate warranty period. Our warranty includes free replacement parts and remote technical support. We also provide extended warranty options for critical systems of the Metal Spiral Corrugated Pipe Mill .