BENTHOMAS Revolutionizes Pipe Production Line with Its Advanced Helibore Technology

News 2025-12-13

Next-Generation Helibore Corrugated Tube Making Machine Delivers Unmatched Efficiency for Helically Corrugation Pipe Mill Operations.

– As global infrastructure demands evolve towards faster, stronger, and more adaptable solutions, the technology behind critical drainage and conveyance systems must keep pace. BENTHOMAS, a leader in industrial roll-forming systems, announces a paradigm shift in manufacturing with its state-of-the-art Helibore Metal Corrugated Pipe Equipment. This integrated line redefines what is possible in the production of high-strength, spiral-wound piping, offering manufacturers a decisive competitive edge.

The conventional methods of producing large-diameter corrugated pipes often involve segmented processes prone to inconsistencies and high waste. Modern projects require seamless, reliable pipes that can be installed rapidly and last for decades. Recognizing this, BENTHOMAS engineers have developed a comprehensive Machine for Helically Steel Corrugated Pipe that integrates the entire production workflow—from coil to finished pipe stack—into one seamless, automated operation.

The Core of Innovation: The Helibore Production System

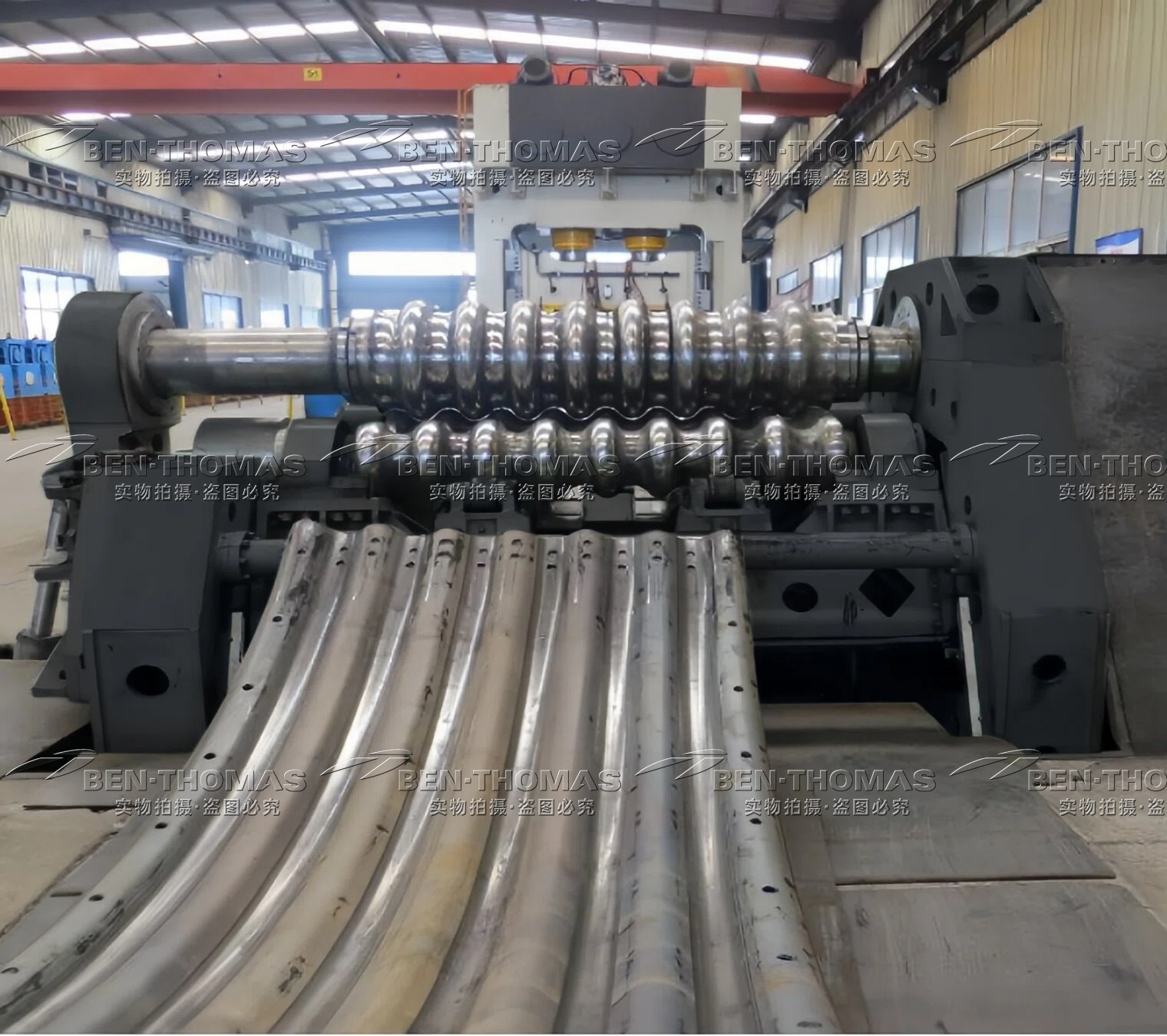

At the heart of this breakthrough is the proprietary Helibore process, a continuous helical forming and welding method. The Helibore Corrugated Tube Making Machine is not merely an iteration of old designs; it is a ground-up re-engineering focused on precision, speed, and robustness.

1. Continuous Helical Forming & Corrugation: Unlike batch processes, our Helically Corrugation Pipe Mill performs corrugation profiling and spiral winding in a single, continuous motion. A flat metal strip is first given its structural rib profile and then immediately fed into the helical winding cage. This synchronous action ensures perfect geometric consistency along the pipe’s entire length, critical for structural integrity.

2. Superior Seam Integrity: The defining feature of the Helibore Metal Corrugated Pipe Equipment is its advanced seam-lock technology. Utilizing a continuous pressure weld or a proprietary mechanical interlock, the machine creates a helical seam that is often stronger than the parent material. This results in a truly monolithic pipe with exceptional leak resistance and the ability to withstand extreme earth loads and internal pressures.

3. Agile and Intelligent Operation: This Machine for Helically Steel Corrugated Pipe is built for flexibility. Pipe diameter changes are achieved through simple programmable adjustments to the forming mandrel and feed angle, eliminating the need for costly, time-consuming tool swaps. Governed by a centralized PLC with an intuitive HMI, operators can manage all parameters—diameter, wall thickness, pitch, and cut length—from a single touchscreen panel.

4. Engineered for Heavy-Duty Output: Designed for 24/7 operation, the line boasts heavy-duty components, from the high-torque decoiler and precision leveling system to the reinforced forming stands and industrial-grade cutting saws. This durability ensures maximum uptime and a rapid return on investment for high-volume production environments.

Transforming Industries with Robust Piping Solutions

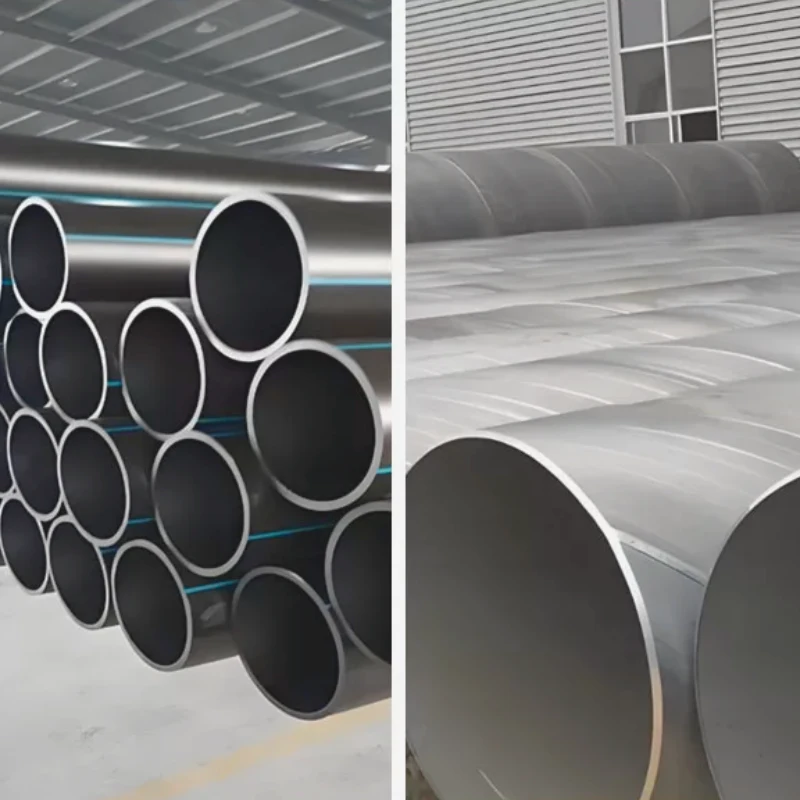

The pipes produced by this advanced line are the backbone of modern infrastructure:

· Public Works: Large-diameter stormwater and sanitary sewer mains for municipal projects.

· Transportation: Culverts and drainage systems for highways, railways, and airports.

· Industrial Applications: Ventilation ducts, piling sleeves, and material conveyance conduits in mining and heavy industry.

· Agriculture: Irrigation and subsurface drainage systems.

By investing in a BENTHOMAS Helically Corrugation Pipe Mill, manufacturers gain the capability to supply these diverse sectors with a superior product, faster and more cost-effectively than ever before.

Commitment to Global Partnerships

“Our new Helibore Corrugated Steel Pipe Line is engineered to solve the core challenges faced by pipe producers worldwide: the need for agility, unwavering quality, and low operational cost,” said Director of Engineering at BENTHOMAS. “We are providing more than a machine; we are providing a turnkey production solution that empowers our partners to lead in their markets.”

About BEN-THOMAS

BEN-THOMAS is a premier designer and manufacturer of specialized metal forming machinery for the global construction and infrastructure sectors.With a legacy of engineering excellence, we deliver robust, automated spiral corrugated culvert pipe production lines that set the standard for quality, efficiency, and innovation in pipe and profile manufacturing.

For detailed specifications, technical sheets, or to schedule a virtual demonstration of our revolutionary Helibore Corrugated Tube Manufacturing Machine, Helibore Metal Corrugated Pipe Equipment, or complete Helically Corrugation Metal Pipe Mill, please visit our website or contact our international sales team.

Contact: Elise Lee

Tel: +86-155 3281 7581

What’s App: +86-155 3281 7581

WeChat: +86-155 3281 7581

Email: elise@tgrollforming.com