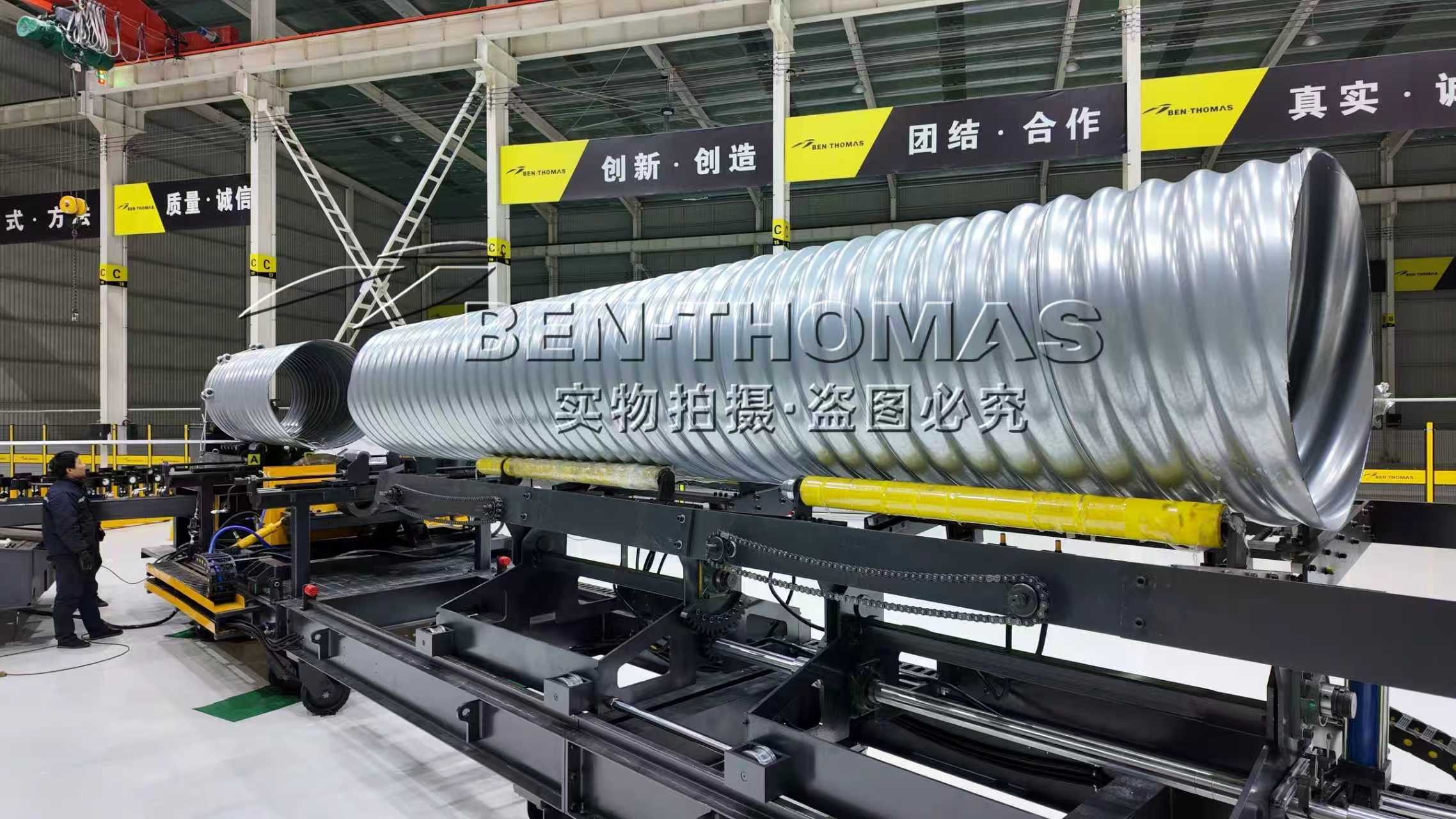

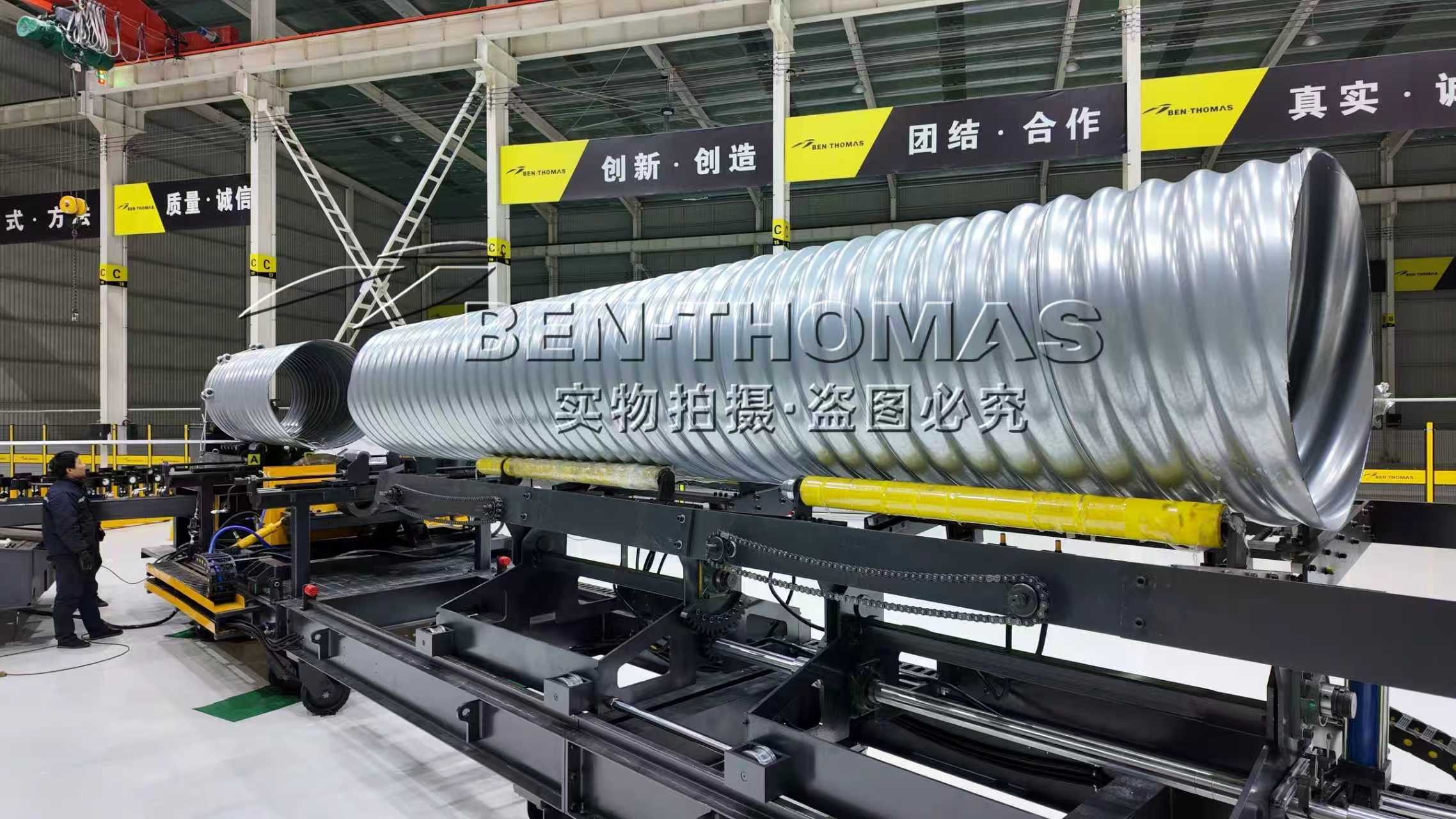

Mobile Corrugated Steel Pipe Machine

No content added

Product Details

As global demand for efficient infrastructure continues to surge, Ben-Thomas, a premier manufacturer of industrial machinery, is proud to showcase its industry-leading Mobile Corrugated Steel Pipe Machine. With decades of specialized production experience, Ben-Thomas has established itself as a global benchmark for quality and innovation in the corrugated pipe industry.

Global Reach and Proven Expertise

Ben-Thomas is not just a manufacturer; we are a partner in global development. Over the years, our Mobile Corrugated Steel Pipe Machines have been successfully exported to dozens of countries across diverse climates and terrains. From high-altitude mountain passes to tropical drainage projects, our Mobile Corrugated Steel Pipe Machine has consistently delivered high-performance results.

Engineering Excellence for Superior Out-put

At the heart of our success lies a perfect production process. Our Mobile Corrugated Steel Pipe Machine is engineered to transform raw steel into high-strength, precision-engineered pipes on-site. This meticulous manufacturing approach ensures that every finished product meets the most stringent international standards for:

* Structural Integrity: Capable of withstanding extreme soil and traffic loads.

* Durability: Advanced galvanization and coating compatibility for long-term corrosion resistance.

* Precision: Perfect interlocking seams and uniform corrugation profiles.

Large-Scale Applications and Client Success

Our technology has been successfully applied to a vast number of culvert projects, drainage systems, and underground passages worldwide. By producing pipes directly at the construction site, our clients have eliminated the logistical nightmares of transporting bulky, pre-fabricated pipes.

“The reliability of the Ben-Thomas Mobile Corrugated Steel Pipe Machine changed our project timeline entirely. We achieved a level of efficiency we didn’t think was possible,” says a lead engineer from a major African infrastructure firm.

Why Choose Ben-Thomas?

The Ben-Thomas Mobile Corrugated Steel Pipe Machine is designed with the investor’s bottom line in mind. Our Mobile Corrugated Steel Pipe Machines offer:

* Stable Operation: Built with heavy-duty components for 24/7 reliability.

* High-Speed Output: Industry-leading production speeds to meet tight deadlines.

* Low Time Costs: Rapid setup and easy maintenance minimize downtime.

* High ROI: Reduced transportation costs and labor efficiency ensure a fast return on investment.

About Ben-Thomas

With decades of engineering heritage, Ben-Thomas continues to lead the way in corrugated steel pipe technology. We remain committed to providing high-quality, stable, and efficient solutions that empower contractors to build the future.

For more information or to request a quote, please visit our website or contact our sales team today.

Frequently Asked Questions

For the metal corrugated pipe production line ,We offer complete in-house tooling design and manufacturing to match your product profiles. After delivery, we provide installation supervision, operator training, and a warranty period. Remote troubleshooting, spare parts supply, and periodic maintenance guidance are also part of our long-term support package.

Yes, our Production Line for Culvert Structural Plate are engineered to process various materials including galvanized steel, aluminum, pre-painted coils, and stainless steel. Material thickness typically ranges from 1.5mm to 12.0mm for Multi Plate Corrugated Culvert Production Line and 1.5mm to 4.0mm for Corrugated Spiral Pipe Production Line. We customize the machine configuration—such as roller hardness, motor power, and control settings—to ensure precise forming and long tooling life for your chosen specification.

Our Multi Plate Corrugated Culvert Production Line and Corrugated Spiral Pipe Production Line feature high automation with integrated PLC control systems that manage speed, length cutting, welding (for pipe lines), and real-time monitoring. Automated sensors detect deviations, and the system can adjust parameters to maintain consistency. This minimizes manual intervention, reduces waste, and ensures each panel or pipe meets precise dimensional and structural standards.

The Spiral Corrugated Pipe Machine Output speed depends on pipe diameter, material thickness, corrugation profile, and welding method. Standard speeds range from 5 to 30 meters per minute. We optimize throughput by configuring heavy-duty decoilers, high-torque spiral forming units, and automated arc welding or seam locking systems—all tailored to your target production rate and product specifications.

We have extensive experience inglobal export packaging and shipping. Mobile Spiral Corrugated Pipe Mill is disassembled into modular, crate-protected sections. Critical components are shock-proof mounted and moisture-sealed. We provide full shipping documentation (packing list, commercial invoice, certificate of origin) and can arrange FOB, CIF, or DAP delivery based on your preference, working with reliable freight forwarders.

We offer a standard18-month warranty from the date of commissioning, covering defects in materials and workmanship for all major components (mainframe, motors, PLC, gearboxes). Consumable parts like forming rolls have a separate warranty period. Our warranty includes free replacement parts and remote technical support. We also provide extended warranty options for critical systems of the Metal Spiral Corrugated Pipe Mill .