Production Line for Culvert Structural Plate

Production line mainly contains :

– Corrugation Profiling ;

– Punching system ;

– Bending system ;

Contact: Elise Lee

Tel: +86-155 3281 7581

What’s App: +86-155 3281 7581

WeChat: +86-155 3281 7581

Email: elise@tgrollforming.com

Product Details

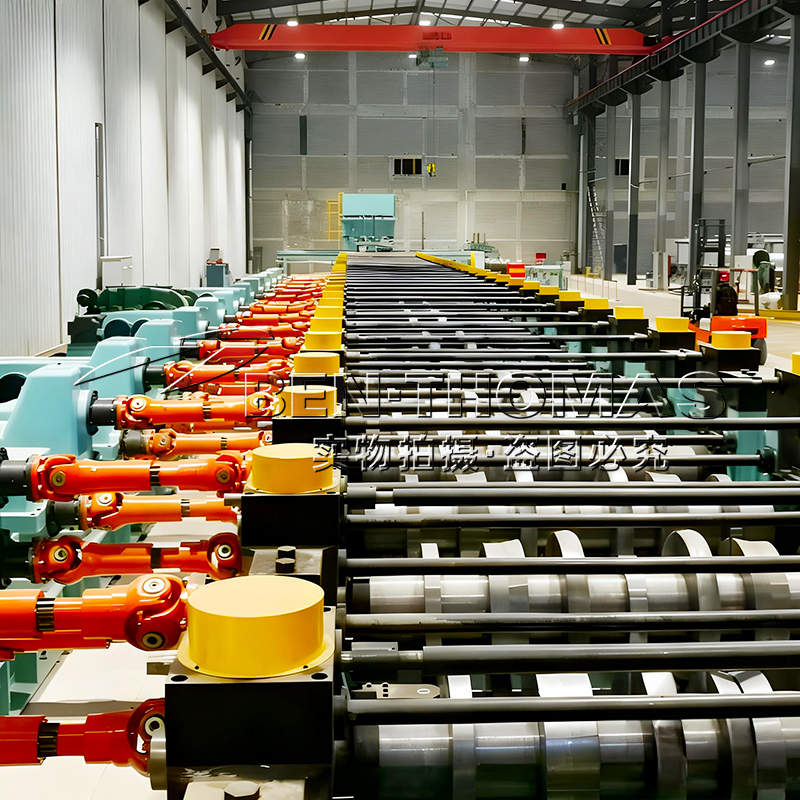

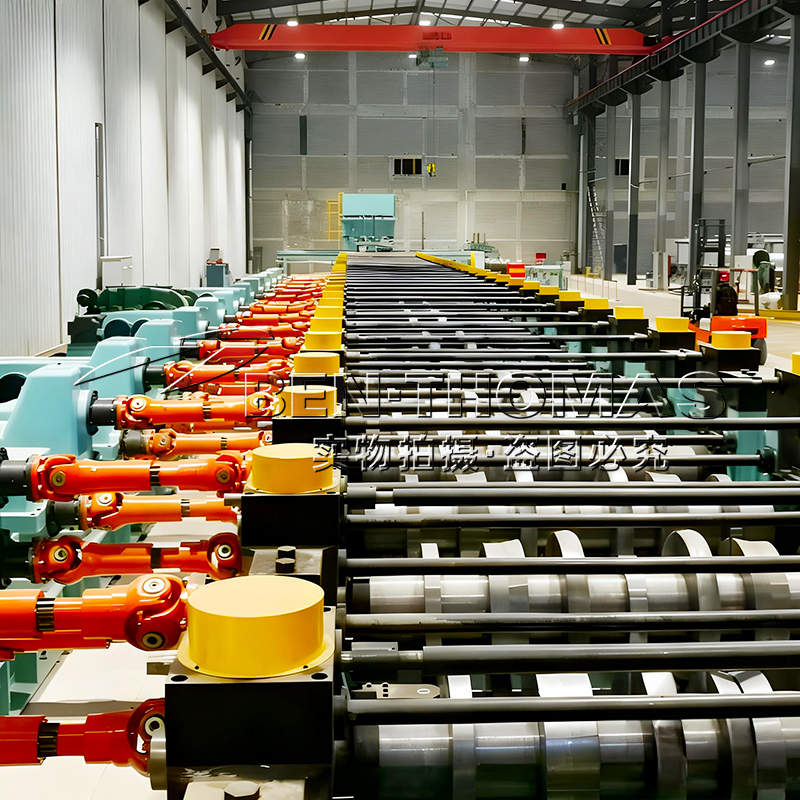

BEN THOMAS Heavy-Duty Corrugated Structural Plate Production Line (1-8mm) – For Drainage, Bridge, Tunnel & Culvert Applications

Introduction

The BEN THOMAS fully-automated corrugated structural plate production line is a state-of-the-art manufacturing solution engineered for the critical components of modern modular infrastructure.It transforms high-strength steel coils (1mm to 8mm thick) into precision-formed, deep-corrugated plates. These plates are designed for rapid assembly into durable structures used across four key sectors: Drainage Systems, Bridge Construction, Tunnel Projects, and Large-Span Culverts. Our corrugated steel culvert and bridges machines delivers the consistent quality, structural integrity, and production efficiency required by global engineering contractors and manufacturers.

Core Machine Configuration & Technical Highlights

1. Heavy-Duty Material Handling & Preparation

· Motorized Decoiler: Handles high-tonnage coils of galvanized, aluminized steel, or ASTM A1011 SS Grades.

· Precision Leveling System: A multi-roll leveler ensures incoming sheet metal is perfectly flat, eliminating coil curvature and yield stress—essential for forming thick, high-strength plates without defects.

2. CNC-Guided Servo Feeding

· An advanced CNC servo feeding system ensures accurate material advance with minimal slippage.

· Integrated edge guiding maintains perfect alignment for symmetrical corrugation formation across the entire plate width.

3. High-Strength Progressive Roll Forming Mill

· The core of the line features a massively constructed mill with large-diameter, carbide-treated forming rolls mounted on reinforced shafts.

· Through multiple forming stages, it progressively creates deep, standardized corrugation profiles that provide exceptional strength-to-weight ratios for earth loads and hydraulic flow.

4. In-Line High-Tonnage CNC Punching Station

· A synchronized, heavy-duty punching unit precisely pierces all connection bolt holes, longitudinal lap joints, and reinforcement slots in a single pass.

· CNC-programmed patterns guarantee hole-to-hole accuracy, enabling fast, secure bolt assembly on-site with perfect seal alignment.

5. PLC Control System with Intuitive HMI

· The entire process is managed by a centralized PLC (Siemens/Allen-Bradley).

· The graphical Human-Machine Interface (HMI) allows for easy input of plate length, hole pattern, curvature radius (for arches), and production batch data. It provides real-time monitoring and diagnostic alerts.

6. Precision Cutting & Automated Handling

· Features a hydraulic flying cut system or high-definition plasma cutter for clean, square cuts at programmed lengths.

· Finished plates are automatically transferred, counted, and stacked by a robotic arm or powered conveyor system, ready for bundling and shipment.

Application-Specific Advantages

· For Drainage & Culverts: Produces plates for Corrugated Steel Pipes (CSP) and Multi-Plate Structures that offer excellent hydraulic efficiency, soil stability, and resistance to abrasion and corrosion in stormwater and agricultural drainage systems.

· For Bridge Construction: Manufactures Bridge Arch Plates and Underpass Systems. The deep corrugations provide immense load-bearing capacity for fill heights, enabling cost-effective, rapid construction of bridge abutments and short-span bridges.

· For Tunnel Projects: Produces Tunnel Liner Plates used in initial ground support, micro-tunneling, and portal construction. The modular plates allow for quick installation and adaptability to various tunnel geometries in mining and transportation projects.

Key Benefits for Your Business

· Unmatched Versatility: One line serves multiple high-demand infrastructure markets.

· Superior Strength & Durability: Handles up to 8mm material, producing plates that meet or exceed AASHTO, ASTM, and EN standards.

· Turnkey Automation: Maximizes output, minimizes labor costs, and ensures consistent, repeatable quality 24/7.

· Precision for Fast Assembly: Accurate hole patterns and profile geometry eliminate onsite fitting issues, drastically reducing construction time.

· Custom-Engineered Solutions: Configurable for various profiles, lengths, curvature diameters, and connection systems per your project specifications.

—

Why Partner with BEN THOMAS?

At BEN THOMAS, we combine decades of machinery manufacturing expertise with a deep understanding of global infrastructure needs. We deliver more than machinery—we provide a complete production solution backed by engineering support, comprehensive training, and reliable after-sales service. Partner with us to equip your factory with the capability to supply critical components for the world’s growing infrastructure projects.

Ready to Build the Future? Contact BEN THOMAS today to discuss your specific application needs and receive a tailored proposal for a production line that will become the cornerstone of your structural plate manufacturing business.

Frequently Asked Questions

For the metal corrugated pipe production line ,We offer complete in-house tooling design and manufacturing to match your product profiles. After delivery, we provide installation supervision, operator training, and a warranty period. Remote troubleshooting, spare parts supply, and periodic maintenance guidance are also part of our long-term support package.

Yes, our Production Line for Culvert Structural Plate are engineered to process various materials including galvanized steel, aluminum, pre-painted coils, and stainless steel. Material thickness typically ranges from 1.5mm to 12.0mm for Multi Plate Corrugated Culvert Production Line and 1.5mm to 4.0mm for Corrugated Spiral Pipe Production Line. We customize the machine configuration—such as roller hardness, motor power, and control settings—to ensure precise forming and long tooling life for your chosen specification.

Our Multi Plate Corrugated Culvert Production Line and Corrugated Spiral Pipe Production Line feature high automation with integrated PLC control systems that manage speed, length cutting, welding (for pipe lines), and real-time monitoring. Automated sensors detect deviations, and the system can adjust parameters to maintain consistency. This minimizes manual intervention, reduces waste, and ensures each panel or pipe meets precise dimensional and structural standards.

The Spiral Corrugated Pipe Machine Output speed depends on pipe diameter, material thickness, corrugation profile, and welding method. Standard speeds range from 5 to 30 meters per minute. We optimize throughput by configuring heavy-duty decoilers, high-torque spiral forming units, and automated arc welding or seam locking systems—all tailored to your target production rate and product specifications.

We have extensive experience inglobal export packaging and shipping. Mobile Spiral Corrugated Pipe Mill is disassembled into modular, crate-protected sections. Critical components are shock-proof mounted and moisture-sealed. We provide full shipping documentation (packing list, commercial invoice, certificate of origin) and can arrange FOB, CIF, or DAP delivery based on your preference, working with reliable freight forwarders.

We offer a standard18-month warranty from the date of commissioning, covering defects in materials and workmanship for all major components (mainframe, motors, PLC, gearboxes). Consumable parts like forming rolls have a separate warranty period. Our warranty includes free replacement parts and remote technical support. We also provide extended warranty options for critical systems of the Metal Spiral Corrugated Pipe Mill .