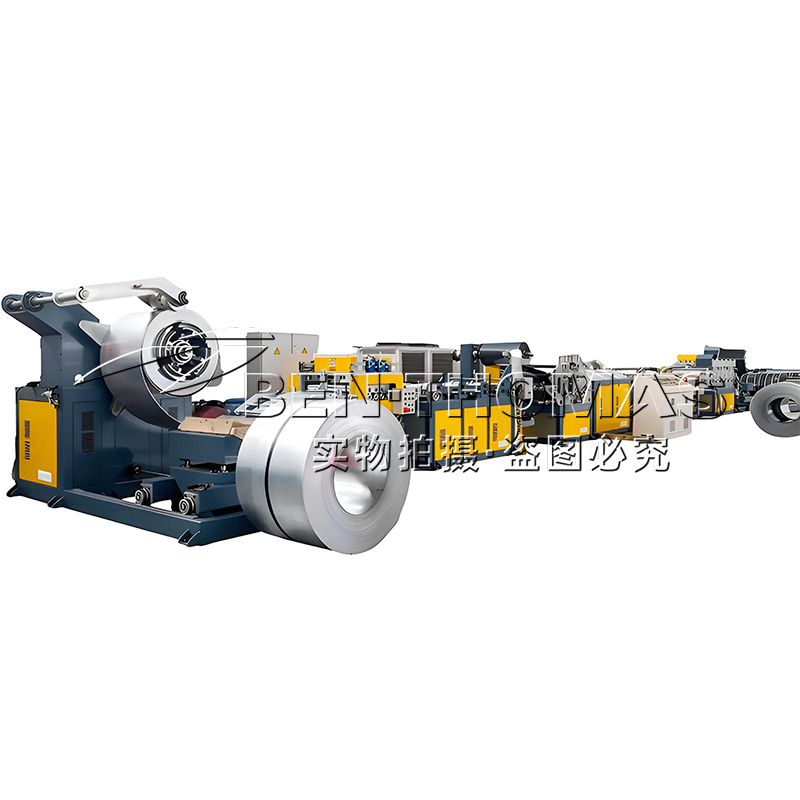

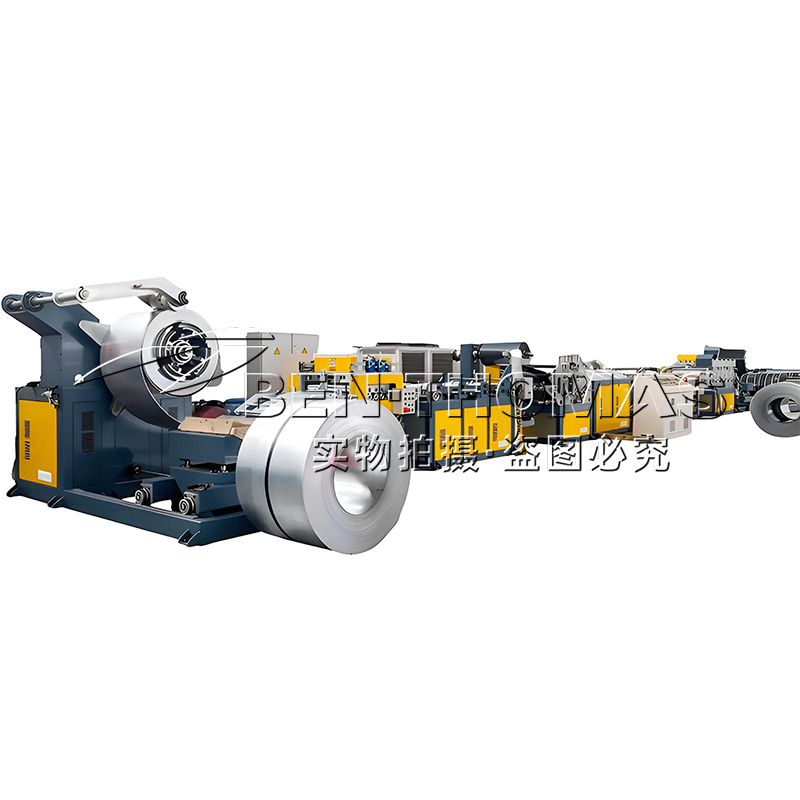

PE Coating Steel Coil Production Line

Contact: Elise Lee

Tel: +86-155 3281 7581

What’s App: +86-155 3281 7581

WeChat: +86-155 3281 7581

Email: elise@tgrollforming.com

Product Details

Our PE Coating Steel Coil Production Line manufactures high-performance PE laminated GI coils. This base material is used to produce corrosion-resistant PE laminated corrugated spiral pipes , ensuring 100-year protection for storm sewers, culverts, and landfill gas recovery systems.

Polyethylene film laminated production line is engineered for a single, critical purpose: to produce the superior base material for the next generation of infrastructure piping. This specialized PE Coating line permanently bonds a tough, chemically-resistant polyethylene (PE) film onto galvanized steel (GI) coil through a precise laminating process. The resulting product—PE laminated galvanized steel coil—is the essential raw material used in the subsequent manufacturing of PE Laminated Corrugated Spiral Pipes . This composite material system is designed to deliver unparalleled, long-term protection in the most demanding environments.

Core Machine Function & Process :

This automated Trenchcoat laminating steel coil production line transforms standard galvanized steel coils into superior composite materials through a precision-controlled process:

Precision Uncoiling & Surface Preparation: The line begins with controlled uncoiling of GI coils, followed by advanced surface treatment to ensure optimal film adhesion.

PE Film Lamination: The heart of the Polyethylene film laminating machine applies specialized polyethylene film through a thermal bonding process, creating a permanent, inseparable barrier on both sides of the galvanized steel substrate.

Quality Control & Curing: Integrated inspection systems monitor coating uniformity and adhesion strength, followed by controlled curing to achieve maximum bond integrity.

Recoiling & Packaging: The finished PE laminated galvanized steel coil is precisely rewound and prepared for shipment to pipe manufacturing facilities.

Key Features of Our Trenchcoat Polymer Coating Machinery

- High-Speed Production: Engineered for maximum throughput while maintaining consistent quality across all production parameters.

- Adaptive Width Compatibility: Handles various coil widths to match downstream pipe manufacturing requirements.

- Precision Thickness Control: Maintains exact PE film thickness specifications for guaranteed corrosion protection.

- Energy-Efficient Design: Incorporates heat recovery systems and optimized power consumption.

- Smart Manufacturing Integration: Compatible with Industry 4.0 protocols for real-time monitoring and production data analytics.

Why Invest in Our Polymer Coating [Laminating] Line?

- Choosing our Polyethylene Film Laminated Production Line provides manufacturers with:

- Market Differentiation: Produce superior corrosion-resistant materials that command premium pricing in infrastructure markets.

- Technical Advantage: Incorporate verified 100-year protection claims into your product offerings.

- Process Efficiency: Automated operation reduces labor costs while improving product consistency.

- Scalable Solution: Modular design allows for future capacity expansions and technology upgrades.

Commitment to Quality & Innovation

Every PE laminating machine we deliver undergoes rigorous testing and validation. Our engineering team provides comprehensive installation support, operator training, and ongoing technical assistance to ensure optimal performance throughout your equipment’s lifecycle.

Frequently Asked Questions

For the metal corrugated pipe production line ,We offer complete in-house tooling design and manufacturing to match your product profiles. After delivery, we provide installation supervision, operator training, and a warranty period. Remote troubleshooting, spare parts supply, and periodic maintenance guidance are also part of our long-term support package.

Yes, our Production Line for Culvert Structural Plate are engineered to process various materials including galvanized steel, aluminum, pre-painted coils, and stainless steel. Material thickness typically ranges from 1.5mm to 12.0mm for Multi Plate Corrugated Culvert Production Line and 1.5mm to 4.0mm for Corrugated Spiral Pipe Production Line. We customize the machine configuration—such as roller hardness, motor power, and control settings—to ensure precise forming and long tooling life for your chosen specification.

Our Multi Plate Corrugated Culvert Production Line and Corrugated Spiral Pipe Production Line feature high automation with integrated PLC control systems that manage speed, length cutting, welding (for pipe lines), and real-time monitoring. Automated sensors detect deviations, and the system can adjust parameters to maintain consistency. This minimizes manual intervention, reduces waste, and ensures each panel or pipe meets precise dimensional and structural standards.

The Spiral Corrugated Pipe Machine Output speed depends on pipe diameter, material thickness, corrugation profile, and welding method. Standard speeds range from 5 to 30 meters per minute. We optimize throughput by configuring heavy-duty decoilers, high-torque spiral forming units, and automated arc welding or seam locking systems—all tailored to your target production rate and product specifications.

We have extensive experience inglobal export packaging and shipping. Mobile Spiral Corrugated Pipe Mill is disassembled into modular, crate-protected sections. Critical components are shock-proof mounted and moisture-sealed. We provide full shipping documentation (packing list, commercial invoice, certificate of origin) and can arrange FOB, CIF, or DAP delivery based on your preference, working with reliable freight forwarders.

We offer a standard18-month warranty from the date of commissioning, covering defects in materials and workmanship for all major components (mainframe, motors, PLC, gearboxes). Consumable parts like forming rolls have a separate warranty period. Our warranty includes free replacement parts and remote technical support. We also provide extended warranty options for critical systems of the Metal Spiral Corrugated Pipe Mill .