What Is the Purpose of Corrugated?

News 2026-01-19

The purpose of corrugated design is to increase strength, manage load, and extend service life by changing shape rather than material.

That’s why corrugated profiles dominate real-world engineering. Flat materials bend early, concentrate stress, and fail faster under load. Corrugation solves those problems through geometry.

What Corrugation Actually Does on the Job

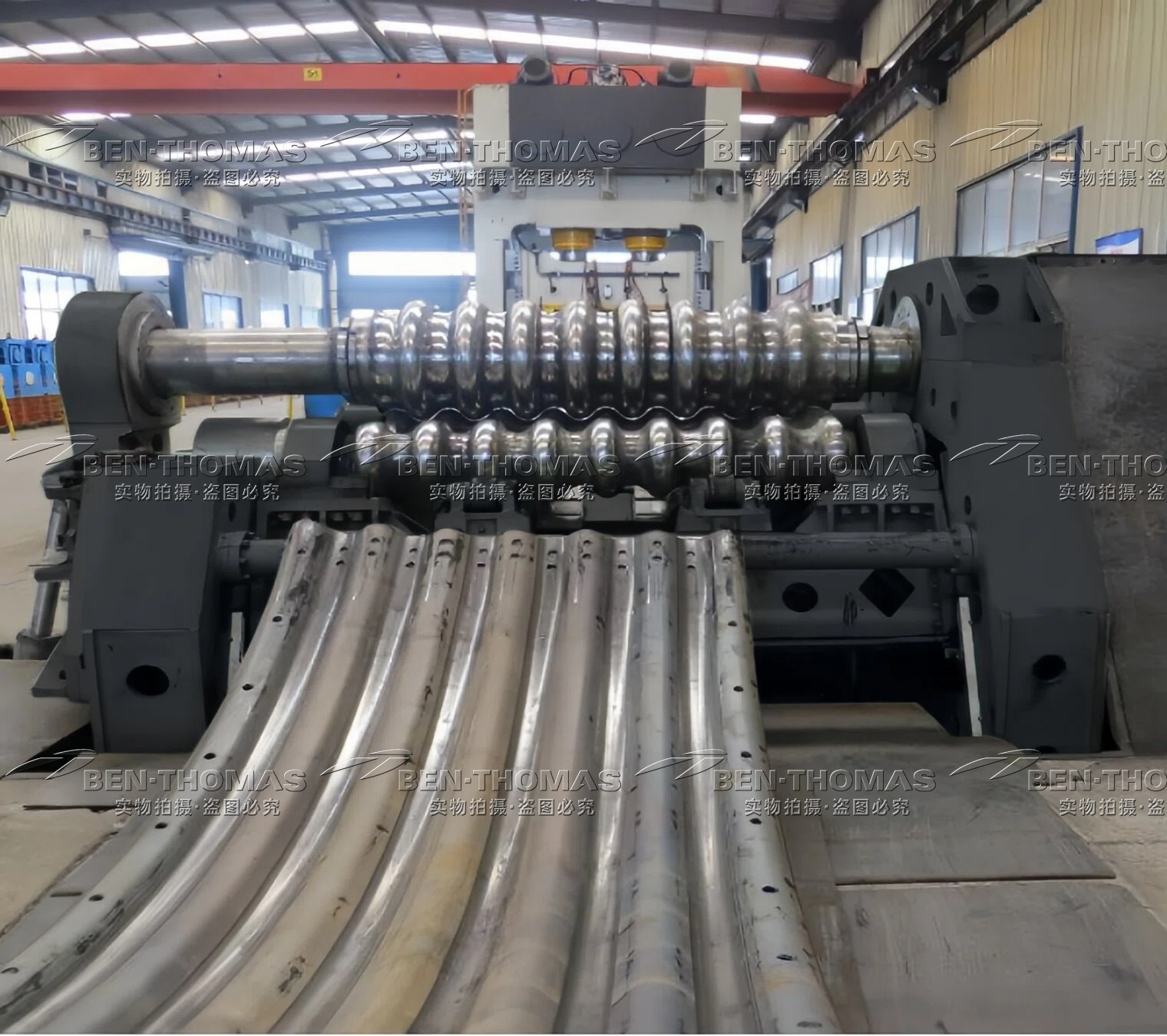

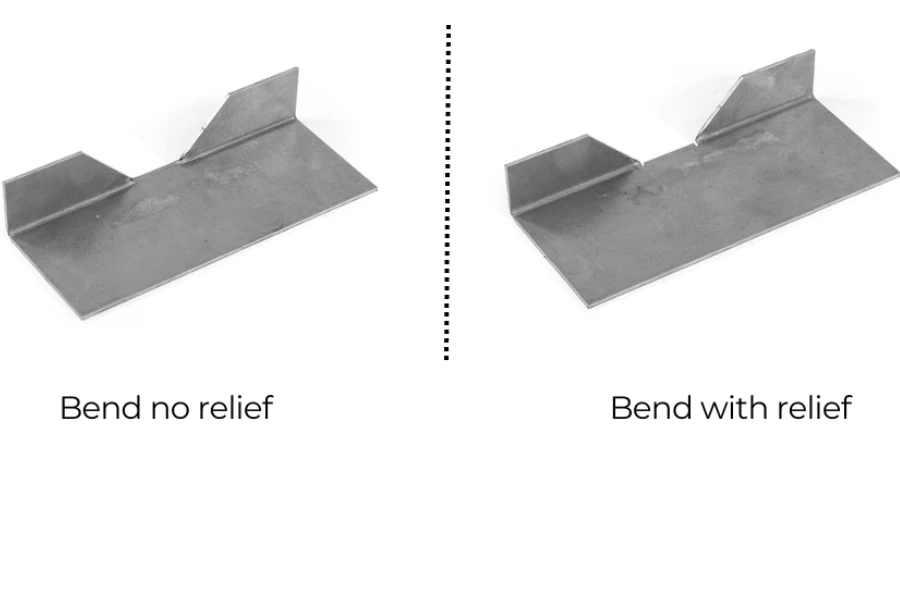

Comparison showing how corrugated shape resists bending better than flat sheet

Lay a flat sheet across supports and add load. Bending starts almost immediately.

The Six Problems Corrugation Solves

1. Strength Without Thicker Steel

Flat panels lose stiffness once deflection begins. Sagging leads to loose fasteners and shortened service life.

Corrugation increases resistance to bending, allowing longer spans without adding thickness.

Result: Higher stiffness without more weight or cost.

2. Spreading Load Instead of Concentrating Stress

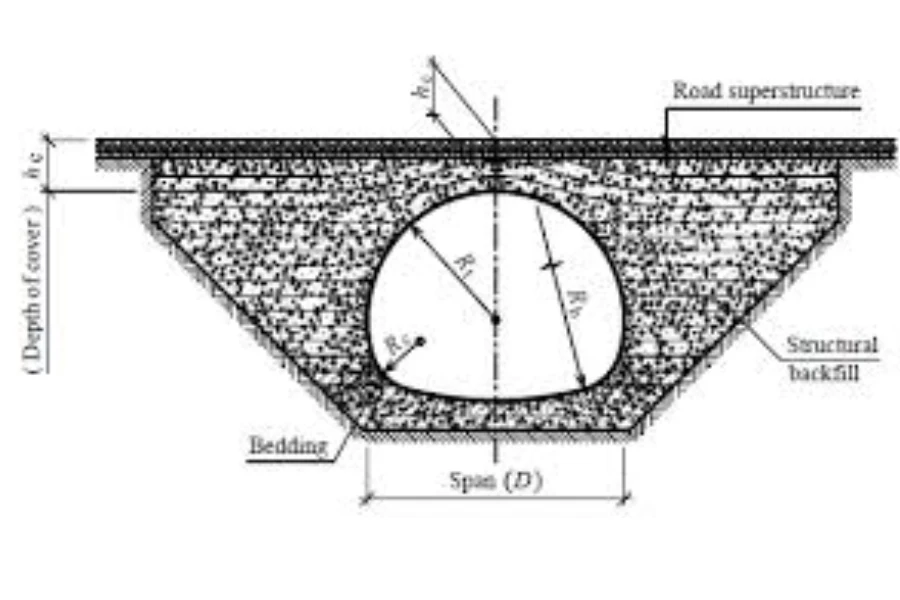

Corrugated pipe distributing soil load evenly to reduce deformation

Soil pressure, wind, snow, and vibration punish flat profiles at narrow stress lines.

Corrugated geometry spreads force along the entire profile.

Result: Lower deformation risk and fewer long-term failures.

3. Handling Impact and Stack Loads

Repeated stacking and compression break weak structures first.

Corrugated cores absorb shock and resist crushing by managing energy through voids.

Result: Force gets absorbed instead of transferred.

4. Flexing Without Cracking

Overly rigid structures fail when soil shifts.

Corrugated pipes allow controlled movement while maintaining strength.

Result: Longer service life under real ground conditions.

5. Moving Water and Reducing Exposure

Standing water accelerates corrosion. Wind uplift adds stress.

Corrugation channels water efficiently and improves resistance to uplift.

Result: Better durability with less maintenance.

6. More Strength Without More Weight

Thicker material increases cost, transport weight, and installation effort.

Corrugated profiles deliver higher performance through shape, not mass.

Result: Efficient structures with predictable costs.

Where Corrugated Shapes Are Used

Corrugation works across industries:

-

Metal roofing and wall panels

-

Steel and plastic drainage pipes

-

Culverts and underground structures

-

Packaging and shipping boxes

-

Temporary fencing and decking

Different uses. Same principle. Geometry replaces extra material.

Why Corrugation Matters in Culverts and Drainage Pipe

Corrugated metal culvert pipe used in highway drainage infrastructure

Culvert failures rarely appear immediately. They show up after backfill settles and traffic loads repeat.

Corrugated metal pipe performs because its profile manages soil pressure and allows controlled movement. Poorly formed corrugation creates uneven stiffness and early deformation.

This is why manufacturers like Ben-Thomas focus on forming stability, profile repeatability, and long-run consistency in corrugated metal pipe production lines.

Better corrugation means fewer failures and higher confidence for owners and contractors.

The Real Reason Corrugated Works

Corrugation exists to solve structural problems through shape.

Its value comes from:

-

Higher stiffness without thicker material

-

Better load distribution

-

Impact and compression resistance

-

Controlled flexibility

-

Improved drainage and durability

-

Stronger strength-to-weight efficiency

Corrugated design doesn’t depend on stronger materials. It depends on smarter geometry.

Machines help, but long-term performance still comes from sound engineering and precise manufacturing.