Which Pipe Has the Longest Lifespan?

News 2026-01-28

You don’t feel pipe life on bid day. You feel it years later when a line starts leaking, the ground settles, or a road crossing needs a shutdown to fix what should’ve lasted.

There’s no single winner in every job. The longest lifespan comes from matching the material to the site, then installing it right.

The Real Cost Shows Up Years Later

Short-life pipe drives the expensive stuff.

-

Rework and traffic control

-

Unplanned outages

-

Callbacks that burn trust

If you’re buying for long-term infrastructure, lifespan is the spec that protects the project.

What Kills Pipes Early on Real Jobsites

Key factors affecting pipe lifespan corrosion load temperature UV installation

Most “material failures” start as site problems.

1. Metal vs. Plastic – Start With the Right “Family”

Metal handles heat, pressure, and load. Plastic wins on corrosion resistance. Choose wrong and you chase leaks and repairs for years.

2. Corrosion and Chemicals – The Silent Life-Reducer

Corrosion eats metal slowly, then shows up as pinholes and joint leaks. Aggressive soils, salt, and industrial runoff accelerate the damage.

3. Stiff vs. Flexible – Settlement Decides the Outcome

Rigid pipe cracks when bedding and compaction aren’t right. Flexible pipe rides out movement better, but only with proper backfill and support.

4. Soil, Water, Heat, Sun – The Site Sets the Rules

Wet soils, stray currents, freeze-thaw, and heavy traffic punish metals. UV and heat punish plastics when crews leave pipe exposed.

5. Install and Upkeep – Where Most Failures Really Begin

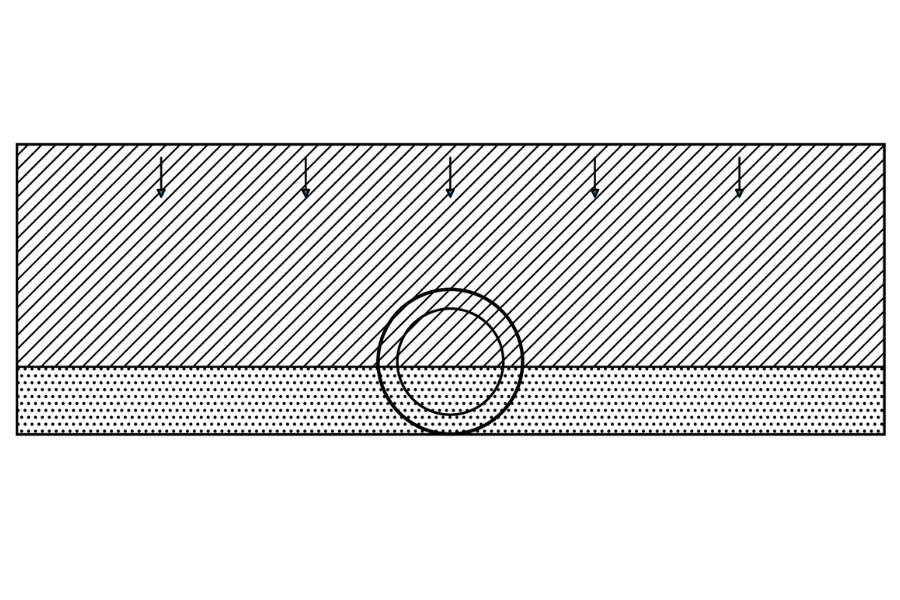

Proper bedding and backfill around a buried pipe to improve service life

Bad bedding, poor compaction, and rushed joints create leaks that return every season. If you want long life, control the install and plan inspections around site risk.

Takeaway: Material matters, but installation decides whether you see the rated life.

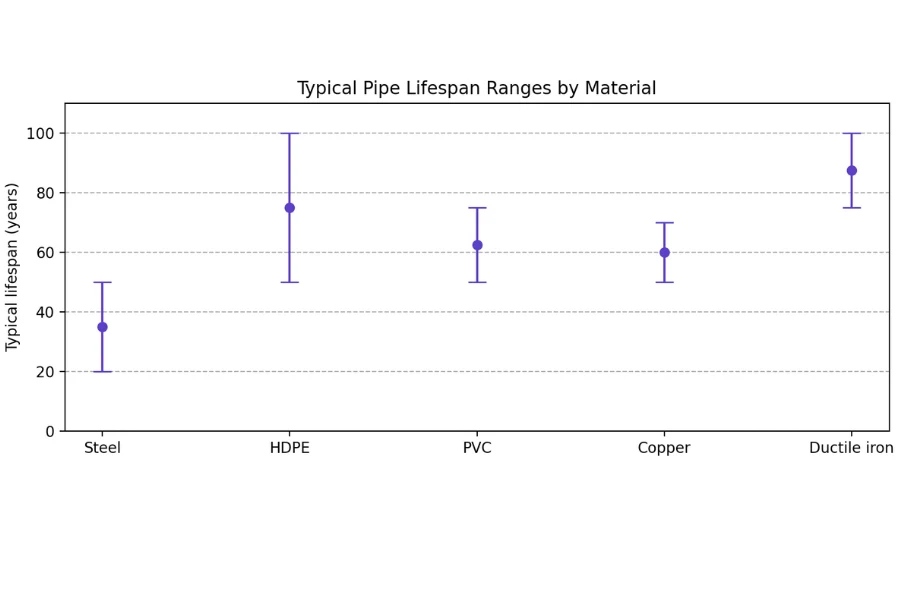

Lifespan Cheat Sheet – What Each Material Usually Delivers

Key factors affecting pipe lifespan corrosion load temperature UV installation

Steel – Strong, But It Rusts If You Let It

-

Typical lifespan: 20–50 years

-

Best for: High pressure, high temperature, structural duty

-

Watch-outs: Needs coatings and often cathodic protection in aggressive soils

HDPE – Built for Buried Work

-

Typical lifespan: 50–100 years

-

Best for: Buried lines in corrosive or chemical-prone soils

-

Watch-outs: Temperature limits and pressure class constraints

PVC – Fine Until It Takes a Hit

-

Typical lifespan: 50–75 years

-

Best for: Drainage and many lower-pressure water systems

-

Watch-outs: Brittle under impact, heavy loads, UV exposure

Copper – Long Life Depends on Water Chemistry

-

Typical lifespan: 50–70 years

-

Best for: Potable water in favorable chemistry

-

Watch-outs: Acidic water risk, higher cost

Ductile Iron – Heavy Duty When Coatings Are Right

-

Typical lifespan: 75–100 years

-

Best for: Municipal water and heavy-load environments

-

Watch-outs: Service life depends on lining and coating integrity

Why Two Materials Keep Winning the Longevity Argument

Why HDPE Usually Beats Steel in Corrosive Soil

Steel life drops when corrosion protection slips. HDPE doesn’t rust and resists many chemicals, so it often delivers longer service underground with less maintenance burden.

Why Ductile Iron Can Run a Long Time Under Load

Ductile iron handles external loads well. With the right lining and coating, it can stay in service for decades, even under roads and heavy traffic.

Where Steel, Copper, and PVC Still Make Sense

-

Steel for high-pressure or high-temperature systems with real corrosion control

-

Copper when water chemistry supports it and budgets allow

-

PVC when loads and UV exposure stay controlled

The Short Answer – Match the Pipe to the Problem

-

Pipe life depends on material + environment + installation + maintenance

-

HDPE often lasts longest in buried, corrosive conditions

-

Ductile iron can reach 75–100 years under load when protection stays intact

-

Steel and copper work when corrosion and chemistry get managed

-

PVC performs well in drainage and lower-pressure work when support and exposure are controlled

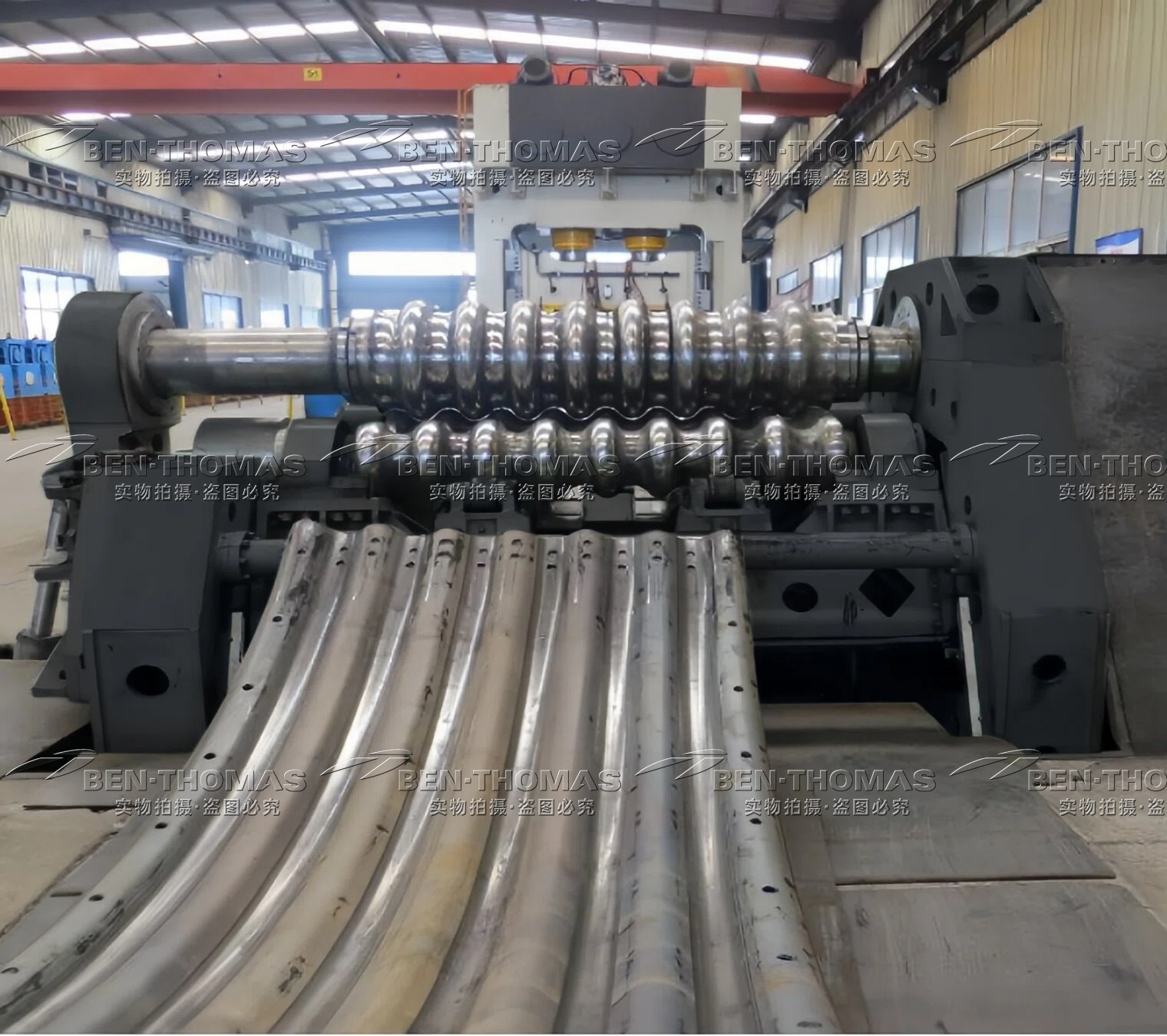

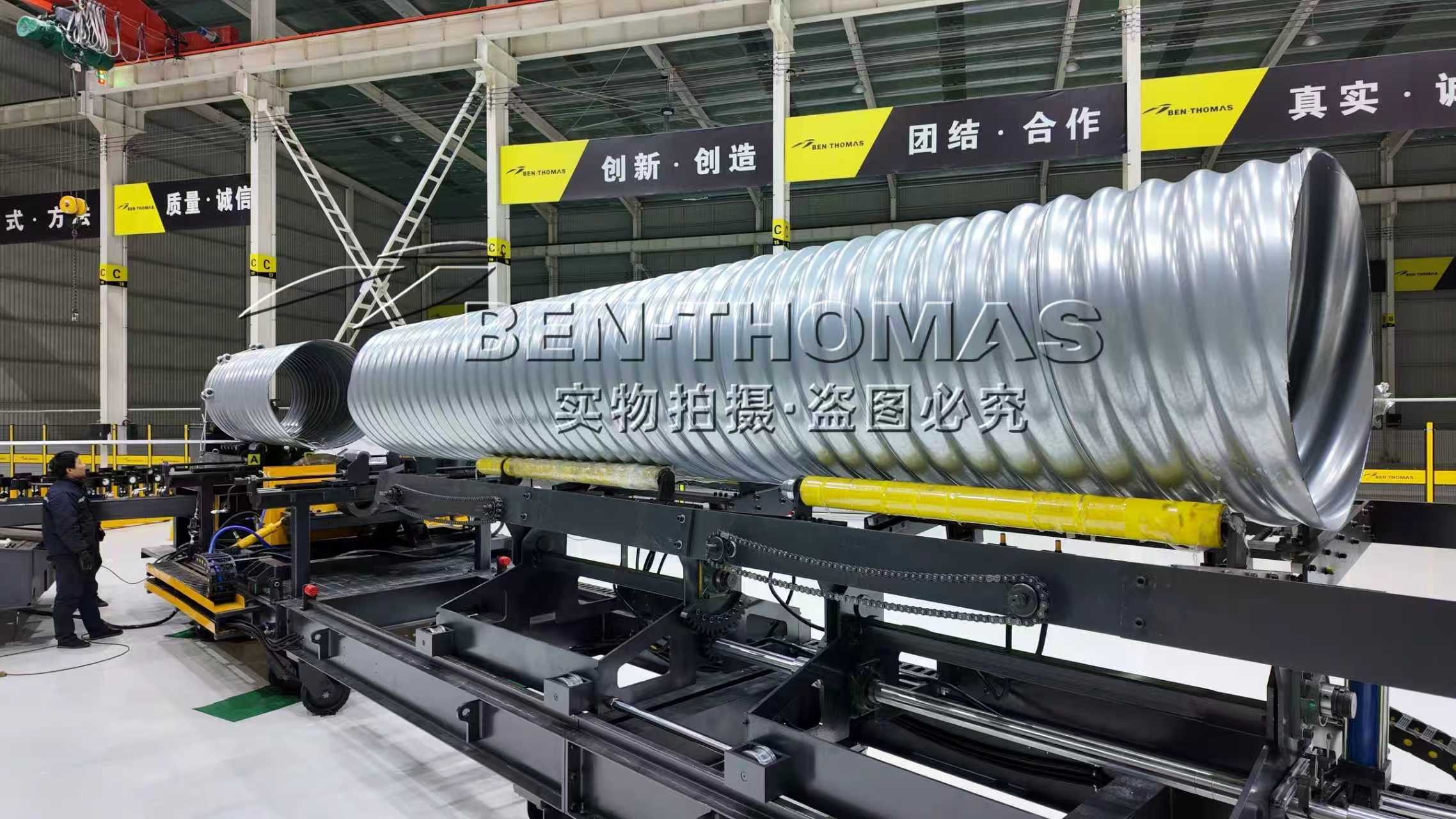

For corrugated culverts and drainage crossings, longevity also depends on manufacturing consistency. Stable corrugation geometry, reliable seaming, and controlled coatings reduce future leak paths and field rework. Ben-Thomas builds complete metal culvert pipe production lines used worldwide — the same reason crews care about lifespan in the first place: fewer comebacks and more trust in the install.

FAQ

Q : Which pipe lasts the longest?

HDPE and well-protected ductile iron usually lead on lifespan. In typical buried service, both can reach 50–100 years when the soil isn’t overly aggressive and the install is done right. The real driver is matching the material to the site, then controlling bedding, backfill, and joints.

Q : Does material type or environment affect pipe lifespan more?

Environment often decides the outcome. A strong material placed in corrosive soil, salty groundwater, or poor bedding can fail early. Meanwhile, a “mid-range” material in stable soil with good drainage can run for decades. Material sets potential life, but the site sets the limit.

Q : Can steel pipes last as long as HDPE?

Steel can run for decades, but it needs a corrosion plan. With coatings, wrap systems, and often cathodic protection, steel life improves a lot. In corrosive soils or chemical exposure, HDPE usually lasts longer because it doesn’t rust and needs less ongoing protection.

Q : Is PVC suitable for long-term projects?

PVC can be a long-life option in the right lane. Many installations reach 50–75 years in moderate conditions, especially for drainage and lower-pressure water. It struggles when impact risk, heavy external loads, or UV exposure are high, and it’s not the first pick for high-pressure systems.